Case Study

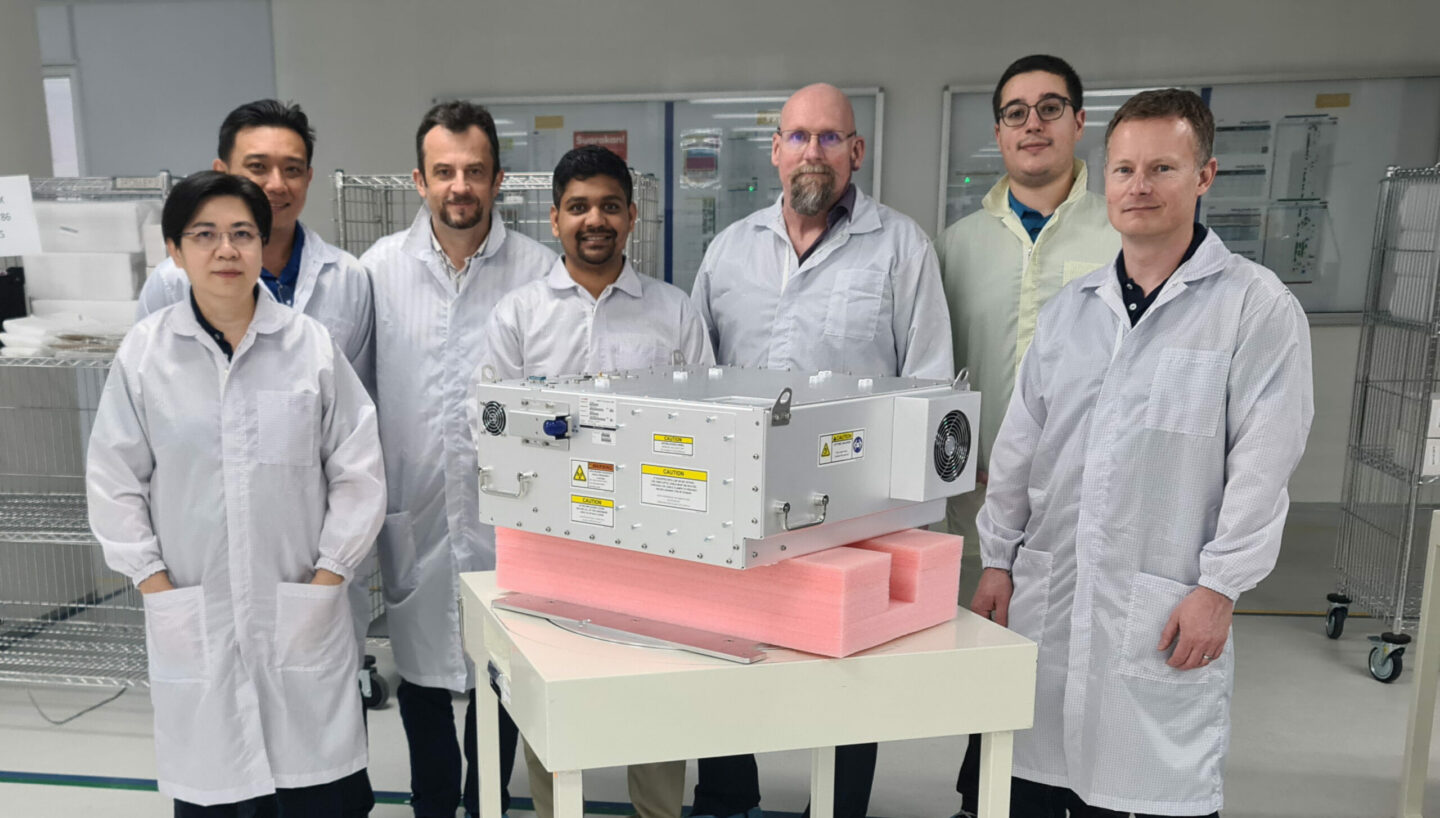

42Q Enables Production Readiness to Double the Volume at Comet’s Penang Facility

The Challenge

Comet’s facility in Penang, Malaysia needed to double the production volume of matching networks within a period of six months. While the manufacturing process itself could support the increase, the manual data collection process had reached the limits of its capability. The company needed to increase efficiency, improve quality, enhance traceability and wanted a single source of truth for all manufacturing data. They decided to implement a Manufacturing Execution System (MES) and eliminate all spreadsheet and paper based processes. They also wanted the system to seamlessly integrate with their ERP system and a variety of manufacturing equipment.

Why 42Q

With only 6 months to research the MES market, select and deploy a system, Comet selected 42Q because of its cloud-based architecture, its rapid implementation, and its integration capabilities with other IT systems.

Results

- 42Q went live on schedule and enabled the doubling of production volume.

- 42Q has become the backbone of all aspects of manufacturing from efficiency improvements to digitalization in general including process control.

- The volume of operating instructions has been significantly reduced by up to 70%.

- Real-time visibility of all manufacturing data in user-friendly dashboards has enabled faster decision-making.

- 42Q has been integrated with five IT systems.