Elevating Cybersecurity in Smart Manufacturing: Strategies and Solutions

Author: Mike Nashadka | Date: June 7, 2024

Elevating cybersecurity in manufacturing: Strategies and solutions

In an era where manufacturing intersects with cutting-edge digital technologies, cybersecurity has emerged as a foundation of operational integrity and reliability. As manufacturers embrace smart manufacturing, the complexity and connectivity of systems increase. This presents new challenges and risks in cybersecurity. This blog explores essential cybersecurity strategies and solutions that can help manufacturers safeguard their operations in a connected world.

The Importance of Cybersecurity in Smart Manufacturing

The advent of Smart Manufacturing has brought about a revolution in efficiency and productivity, but has also introduced new risks. Cybersecurity threats can compromise not only financial and operational aspects but also the safety of employees and customers. Protecting manufacturing data, intellectual property, and the integrity of automated processes is paramount. At the core of an effective cybersecurity strategy are the three fundamental principles of: Confidentiality, Integrity, and Availability. Ensuring these principles are upheld is essential to safeguarding manufacturing operations in a connected world.

Strategies for strengthening cybersecurity

Risk assessment

Regularly evaluate your manufacturing systems and processes to identify potential vulnerabilities. This involves conducting comprehensive security audits, performing penetration testing, and continuously monitoring for any unusual activities. For example, a manufacturing company might conduct quarterly security assessments to uncover and address risks before they can be exploited. By identifying potential threats early, manufacturers can implement targeted cybersecurity measures that are specific to their unique operational needs.

Layered security approach

Implement multiple layers of security, including firewalls, intrusion detection/prevention systems (IDS/IPS), and encryption to protect manufacturing networks and devices. This Defense-in-Depth strategy provides several lines of defense, making it harder for attackers to penetrate systems. Additionally, employing Endpoint Detection and Response (EDR) solutions helps monitor and respond to threats in real-time. For instance, 42Q's systems utilize advanced SIEM (Security Information and Event Management) technologies to provide real-time analysis of security alerts generated by hardware and applications.

Employee training

Educate your staff about cybersecurity best practices and the importance of maintaining secure systems. Human error is often the weakest link in cybersecurity defenses. To mitigate this, implement ongoing training programs and regular phishing simulations to ensure employees remain vigilant and informed. For example, conduct monthly workshops and quarterly simulations to keep cybersecurity top-of-mind and reinforce the importance of adhering to security protocols.

Regular updates and patches

Ensure that all software and hardware are up to date with the latest security patches. Vulnerabilities in outdated systems can serve as entry points for cyberattacks. Establish, and follow, a documented routine to identify & mitigate these risks. For instance, set up automated patch management systems to regularly check for and apply updates, reducing the window of opportunity for potential attacks. Regularly reviewing and updating security policies can also help keep defenses aligned with evolving threats.

Collaboration with experts

Work with cybersecurity experts and service providers who specialize in industrial environments. Their expertise can help tailor cybersecurity solutions to the unique needs of smart manufacturing. Regular third-party audits and compliance checks, such as achieving SOC 2 Type 2 certification, demonstrate a strong commitment to cybersecurity. For example, partnering with a cybersecurity firm to perform annual audits ensures that security measures are effective and up-to-date. Additionally, leveraging expert guidance can aid in developing robust incident response plans to swiftly address any breaches.

Solutions for cybersecurity in manufacturing

Adopting a proactive approach to cybersecurity involves integrating advanced solutions that can preemptively identify and mitigate threats. 42Q employs real-time monitoring systems that continuously scan for vulnerabilities and potential breaches across all connected devices. Their AI-driven threat detection algorithms analyze data patterns to identify and respond to anomalies before they can escalate into serious threats.

Moreover, 42Q utilizes secure cloud storage solutions to safeguard sensitive manufacturing data, ensuring that all information is encrypted both in transit and at rest. This not only protects against data breaches but also ensures compliance with industry regulations. Additionally, 42Q's platforms come equipped with integrated cybersecurity features such as automated patch management and multifactor authentication, streamlining the implementation of robust security measures and reducing the burden on IT teams.

42Q's integration with SIEM systems enables comprehensive real-time analysis and correlation of security events, providing a holistic view of the security landscape and facilitating quick responses to potential threats. By leveraging these advanced technologies and tools, 42Q helps manufacturers enhance their cybersecurity posture, protect their operations, and maintain the integrity of their smart manufacturing environments.

Conclusion

42Q’s digital transformation solutions for manufacturing are designed with security at their core. Offering end-to-end encryption for interfaces and APIs, multiple levels of network security including firewalls, regular security updates, and compliance with industry standards (i.e. SOC 2 Type 2), 42Q helps manufacturers protect their operations from cyberthreats while enabling the benefits of smart manufacturing.

Navigating the New Digital Era: The Fourth Industrial Revolution and 42Q’s Role

Author: Wellington Giolo | Date: April 3, 2024

Navigating the New Digital Era: The Fourth Industrial Revolution

The Fourth Industrial Revolution (4IR) represents a fundamental shift in the way we live, work, and relate to one another. It is characterized by a fusion of technologies that blur the lines between the physical, digital, and biological spheres. 4IR is particularly significant for industry, and 42Q’s solutions and its partnership with AWS are pivotal in navigating this transformation.

The pillars of the Fourth Industrial Revolution

4IR is built on the integration of advanced technologies such as artificial intelligence, the Internet of Things (IoT), robotics, and 3D printing. These technologies enable an interconnected and intelligent industrial ecosystem, offering unprecedented opportunities for productivity and growth.

The impact of 4IR on industries

The advent of 4IR is transforming industries by enabling more flexible, efficient, and customer-focused production and service models. It encourages innovation, enhances operational efficiency, and facilitates the creation of new value chains and business models. However, it also presents challenges, including cybersecurity concerns, the need for skilled labor, and the importance of sustainable development.

42Q’s contribution to navigating 4IR

42Q, in partnership with AWS, is at the forefront of helping businesses embrace the opportunities of 4IR. Their cloud-based collaborations offer the agility, scalability, and security that industries need to thrive. These solutions are critical for adapting to and leading in the new digital era.

Enhancing Operational Efficiency

42Q’s solutions streamline manufacturing processes by taking full advantage of the scalability and flexibility of cloud computing. Integrating AI and IoT technologies, these systems automate routine tasks, reduce human error, and optimize production schedules. This leads to more efficient use of resources, lower costs, and faster time to market. Real-time data processing capabilities let manufacturers quickly adjust to changes in demand, supply chain disruptions, or other operational challenges, ensuring that production is always running at peak efficiency.

Enabling Predictive Maintenance

Predictive maintenance is another area where 42Q’s solutions excel. Advanced analytics and machine learning algorithms predict equipment failures before they happen, scheduling maintenance only when needed. This proactive approach reduces downtime, extends the life of machinery, and cuts down on unexpected repair costs. By analyzing historical data and identifying patterns, 42Q’s solutions can also recommend improvements in maintenance schedules and operational practices, further enhancing the longevity and reliability of production equipment.

Informing Decision Making with Real-Time Analytics

The ability to make informed decisions quickly is crucial in today’s fast-paced manufacturing environments. 42Q’s solutions provide managers and operators with real-time analytics and insight into every aspect of the production process. From monitoring the performance of individual machines to tracking the efficiency of entire production lines, 42Q’s analytics tools help identify bottlenecks, assess productivity, and uncover opportunities for improvement. This data-driven approach ensures that decision makers have the information they need to optimize operations, improve product quality, and respond to market trends with agility.

Employing the Full Potential of 4IR Technologies

The integration of 42Q solutions with the robust AWS cloud infrastructure enables businesses to take full advantage of the potential of 4IR technologies. Whether it’s employing AI for smarter production planning, using IoT devices for enhanced monitoring and control, or applying big data analytics for deeper insights, 42Q and AWS together provide a comprehensive platform that supports the digital transformation journey. This synergy empowers businesses to navigate the challenges of the Fourth Industrial Revolution and positions them to capitalize on its opportunities.

Conclusion

The Fourth Industrial Revolution is reshaping the industrial world, offering both challenges and opportunities. As businesses seek to navigate this new era, partnerships such as the 42Q/AWS collaboration will be crucial for harnessing the power of digital transformation. By embracing these changes, businesses can unlock new levels of innovation, efficiency, and growth.

Revolutionizing Manufacturing: 42Q’s Cloud-Based MES on AWS

Author: Wellington Giolo | Date: February 28, 2024

Introduction: Pioneering Sustainable Manufacturing with 42Q

In the era of digital transformation, sustainability has become a pivotal concern for manufacturers. 42Q, a Sanmina division, stands at the forefront of this revolution as the only full-featured, cloud-based Manufacturing Execution System (MES) hosted on Amazon Web Services (AWS). This blog explores how 42Q leverages the power of cloud computing to enhance sustainability in manufacturing processes.

The Edge of Cloud-Based MES in Manufacturing

Transforming Operations with 42Q’s Cloud-Based MES

Research conducted by the international analyst firm 451 Research indicates that migrating on-premises workloads to AWS can significantly reduce the workload carbon footprint by at least 80%, a figure that can climb to an impressive 96% once AWS attains its 100% renewable energy goal by 2025. You can learn more about how workloads on AWS are helping enterprises meet their carbon neutral and sustainability targets here.

42Q’s cloud-based MES is built on the AWS cloud so that 42Q customers can benefit from both the AWS cloud infrastructure sustainability commitments and the efficiencies and optimizations that support companies reaching carbon neutral commitments. By rapidly digitizing shop floor operations and improving efficiency and transparency across supply chains, 42Q MES eliminates on-premises hardware while empowering manufacturers with real-time visibility and actionable insights, essential for driving sustainable practices.

Achieving Sustainability Through AWS Integration

AWS’s focus on efficiency and renewable energy—aiming for 100% renewable energy usage by 2025—significantly contributes to reducing the carbon footprint of cloud-based operations. This was a significant factor in 42Q selecting AWS as its cloud partner and making 42Q the only fully featured cloud MES solution in the market today. This integration allows 42Q to offer a solution that not only optimizes manufacturing processes but also aligns with global sustainability goals.

Success Stories: 42Q in Action

A Global Manufacturer: A Case of Enhanced Efficiency

By modernizing to 42Q MES, A global manufacturer was able to remove over 500 servers from their facilities. 42Q’s multi-tenant solution operates on AWS’s energy-efficient and environmentally friendly cloud platform, allowing the manufacturer to continue to support its customers without the overhead necessary in traditional on-premises systems.

The Future is Green and Cloud-Powered

42Q and AWS: Partners in Sustainable Manufacturing

42Q’s unique position as a cloud-based MES provider creates a powerful synergy when combined with AWS’s sustainable cloud computing initiatives. This partnership is driving the future of manufacturing towards a more sustainable, efficient, and carbon-neutral direction.

Embracing Cloud Technology for Eco-Friendly Manufacturing

The adoption of 42Q’s cloud-based MES is more than a technological upgrade; it’s a step towards a greener future. By leveraging AWS’s sustainable infrastructure, 42Q offers manufacturers a path to reduce environmental impact while enhancing operational efficiency.

Conclusion: Leading the Way with 42Q’s Cloud-Based MES

42Q, through its innovative cloud-based MES solution on AWS, is redefining manufacturing. It offers a pathway for companies to embrace digital transformation while contributing to a sustainable future. By choosing 42Q, manufacturers are not just optimizing their processes; they are actively participating in the global movement towards sustainability. 42Q is excited to support our customers and AWS on their carbon-footprint reduction strategy.

Introducing 42Q Smart Manufacturing V16.0

Author: Wellington Giolo | Date: November 12, 2023

I am thrilled to announce that we have just unveiled our latest groundbreaking platform: 42Q Smart Manufacturing V16.0. We have always been at the forefront of manufacturing innovation, continuously pioneering new capabilities for modern manufacturers like you, and this release is no exception. In my 30+ years working in this industry—and for the past 25 years at 42Q—I could not be prouder of the way we collaborate with and then respond to our customers with capabilities that none of our competitors can touch.

We are manufacturers, building solutions for manufacturers. Our expertise really shows up in the details and our proof is in our incredibly high levels of customer satisfaction. Take a read through what we are offering with 42Q Smart Manufacturing V16.0 and then let me know what you think.

You’re unique – your MES should support that

Traditionally, manufacturers have had to conform to the limitations of their chosen MES solution, adjusting their workflow and terminology to fit the system. However, with the release of 42Q Smart Manufacturing V16.0, we are putting the power back into the hands of our customers, enabling you to take control and shape your MES environment according to your unique needs.

Create dynamic user interfaces for streamlining and greater control

Our platform offers unprecedented flexibility by allowing you to compose dynamic user interfaces through the arrangement of modular components, essentially making it composable, not just customizable. This is important because it saves time and money, enabling you to respond to the changing needs of your business as you evolve to meet market demand and regulatory requirements. You can select from a range of pre-designed widgets or even create your own using a low-code approach. This empowers you to perform all necessary tasks in one centralized location, seamlessly integrate data from various systems, and configure specialized process flows tailored to your manufacturing processes.

Personalize your terminology, simplify your user experience to reduce training time, and improve quality

We understand that precision and clarity are paramount in manufacturing operations, where industry-specific terminology often plays a crucial role. 42Q Smart Manufacturing V16.0, addresses this challenge by intelligently recognizing and adapting to industry-specific terminology. Your communication aligns seamlessly with regulatory compliance and industry standards, eliminating any confusion and enhancing operational efficiency.

Furthermore, we know that in today’s interconnected world, you need to support global collaboration. Typically, manufacturers rely on MES providers for language translations, but our platform allows you to effortlessly localize the user interface. This localization capability ensures that your manufacturing environment is optimized for international collaboration, significantly enhancing your worldwide operations and supply chain.

Built by manufacturers, for manufacturers

When manufacturing excellence is in your DNA after 40+ years of perfecting global manufacturing operations, then you know exactly how to build and deploy a comprehensive, cloud-based MES solution. From shop floor to operations teams to the executive suite, our solution is the most straightforward way to expedite the digital transformation of your factory operations. What’s more, we can have this solution up and running within a matter of weeks, significantly mitigating the risks and disruptions that often come with such transitions.

With 42Q, you gain access to a wide range of essential features, including full product traceability, route enforcement, cycle time monitoring, asset performance optimization, defect and repair loop management, electronic work instructions, serialization, and much more. Our architecture is not only accessible and reliable but also highly scalable and secure, ensuring that your manufacturing processes always run smoothly and efficiently.

If you want to learn how we can transform your manufacturing operations in only four weeks, reach out to me at wellington.giolo@42-q.com.

OEE

(Overall Equipment

Effectiveness)

Author: Gustavo Velasquez | Date: August 16, 2022

Your factory’s blood pressure, heart rate and oxygen levels monitored in real-time.

An essential part of manufacturing is the ability to quantify the productivity and efficiency of production processes and assets. Everything that can be measured, monitored, and managed can likely be optimized. This, by itself, is already a great reason for implementing OEE-based continuous improvement programs.

OEE is a tremendous benefit to organizations by helping with early detection and providing actionable intelligence to different user bases across the enterprise, whenever availability, performance, or quality aren’t looking as good as they should. OEE is considered a gold standard measurement of how well production lines and assets are running, and this information is critical to determining benchmarks and identifying areas for improvement.

Businesses can monitor and compare the actual effectiveness of production processes and assets and quickly identify issues, allowing troubleshooting and optimizations to resolve the underlying causes of availability, performance, and quality problems.

What is OEE?

OEE (Overall Equipment Effectiveness), in simple terms, is an index that measures how effective any piece of equipment is. You can think of it as a medical monitor that gathers and computes your asset’s blood pressure, heart rate and oxygen levels continuously displaying and keeping the history of these KPIs and raising alerts when things are out of control.

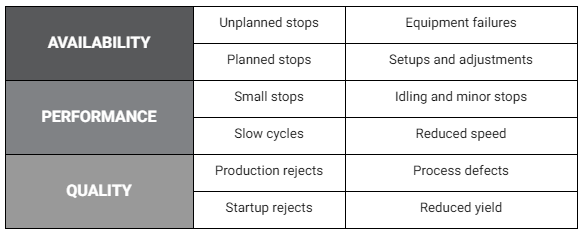

When a well-rounded, integrated OEE system such as 42Q is implemented, operations can quickly unleash the power of clusters of OT information that were previously isolated and very difficult to make sense of. The losses are related to the three main factors that link to poor OEE and can be investigated by any organizational level you desire. The chart below shows the six big losses that manufacturing leaders keep their eyes on for their production lines and processes.

Monitoring and taking action on these metrics is one of the key differentiators between world-class manufacturers and the rest of the pack. Don’t worry, though, help is on the way. If you’re reading this, you’ve already taken the first few steps towards the answer that will help visualize issues and improvement opportunities.

Overall Equipment Effectiveness is the product of the 3 KPIs/metrics above:

OEE = Availability * Performance * Quality

An effective analysis of the underlying causes for losses in any of those 3 main process indicators is a science that requires readily available information; the flexibility to quickly and easily interpret business intelligence and monitoring capabilities while controlling the cost of acquiring all that data, processing it into valuable information and making it available anywhere at any time.

An OEE system that acts in the backstage in a nearly transparent fashion to the operations is the holy grail manufacturers all over the world have been looking for. 42Q can deliver all of that and more.

The OEE components: Availability, Performance, and Quality.

Each underlying variable in OEE corresponds to a specific type of loss. Knowing with confidence that accurate calculations will identify potential production losses, this will in turn will lead to better decision-making, saving time and resources.

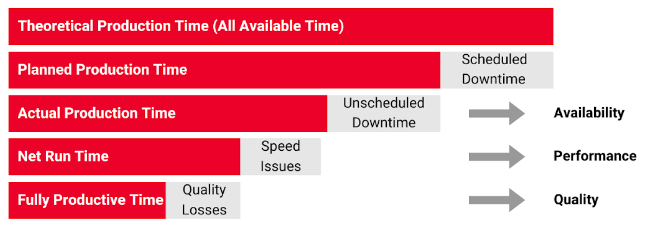

Availability

This KPI compares the time that an asset was operating against the time that it was stopped. It is the relationship between the actual production time (planned production time minus every stoppage, including scheduled and unscheduled downtimes) and the originally planned production time.

Scheduled downtimes are planned events such as personnel breaks, meal times, shift changeovers and other times when production isn’t scheduled to be running. OEE systems should allow for the categorization of downtime events and scheduled downtimes would not be counted as availability loss.

Availability = Actual Production Time / Planned Production Time

Performance

This KPI provides information about how fast a part is being produced. It compares the actual production speed (total count / actual production time) against the theoretical target run rate. Performance is affected by minor stops and slowdowns making production run at less than the ideal cycle time.

Performance = (Total Count / Actual Production Time) / Target Run Rate

Quality

The quality variable shows how many good units were produced versus the total count. It is affected by rejected products. This calculation takes into account good manufactured parts that go through the process for the first time without any rework and divides it by the total number of parts processed.

Quality = Good Units / Total Count

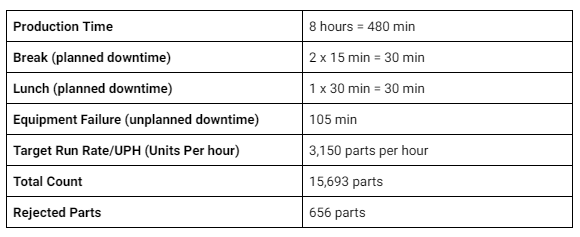

Practical Example

Let’s say that each Friday the operations manager and his team review a weekly OEE trend by manufacturing line or asset.

During their last meeting, they identified the current top five OEE downtime reason codes. The next step was to detect the specific downtime root causes and which machines are experiencing unplanned downtimes due to equipment failure. Afterward, they might want to also drill down even further to find detailed repair information to figure out the most common causes, problems, and repair actions that are resulting in asset downtime.

This type of analysis allows operations management and maintenance teams to make informed decisions and take corrective action to prevent or reduce downtimes. In the upcoming OEE weekly meeting, the team can review the trends and compare them with previous periods (i.e. before and after corrective action plans, supplier changes, staff training, and other potential actions).

The following is a simple example that helps to explain how OEE is calculated:

Note: This is fictional data used to explain how OEE calculation may help build the underlying variable(s) that are used to display improvement opportunities.

What can monitoring OEE do for your factory?

- Measure accurately and effectively. Production constraints and bottlenecks can be quickly identified through OEE data analysis, uncovering opportunities to rectify weaknesses thereby improving your processes and machinery. For example, if a production line is capable of producing 100 pieces per hour, but it is producing less than that, OEE systems will point that out.

- Improve Return on Investment (ROI). Assets are expensive. Using them to the fullest can represent an important step towards operational excellence and profitability. OEE provides measurable KPIs that can be used to gauge and monitor efficiency over time, directly supporting decision-making on maintenance plans, material supply processes, staff training, machine purchases, and more.

- Cost savings. By utilizing OEE and analyzing the underlying metrics, teams can identify losses and work on minimizing defective products, and reworks machine slowdowns, and unplanned downtimes, which translates into cost savings.

- Predict/Prevent breakdowns. As OEE provides real-time machinery efficiency information, it helps companies to prevent or control machine failures. This could lead to less unscheduled downtimes, especially when it is integrated with a Computerized Maintenance Management System (CMMS) that calculates the mean time between failures (MTBF) and mean time to repair (MTTR).

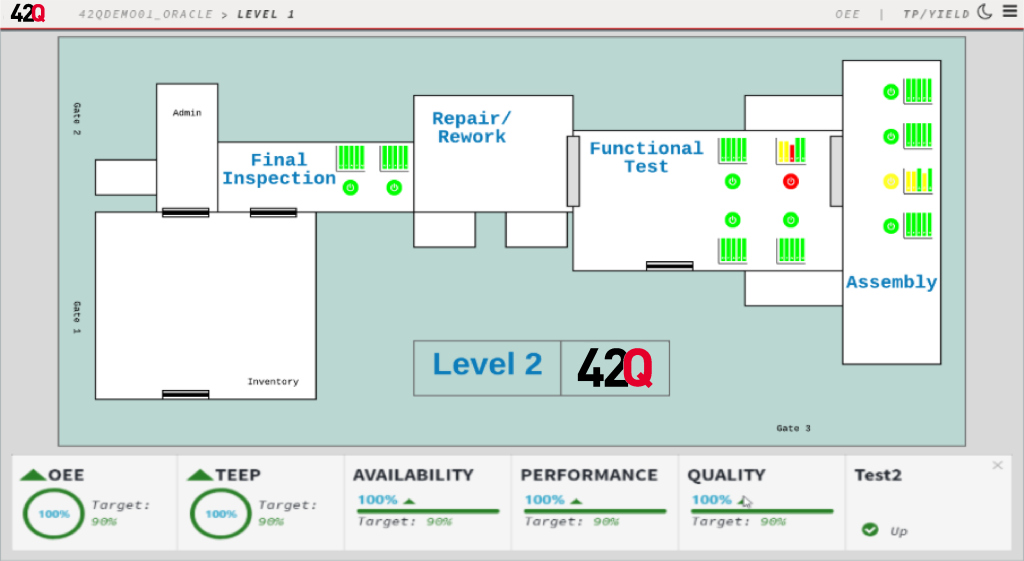

OEE in 42Q

The set of functionality provided by 42Q’s OEE system includes several features around data collection, analysis, and reporting through a clear and intuitive user interface. Additionally, it is easy to implement machine connectivity through 42Q’s IIoT modules.

![]()

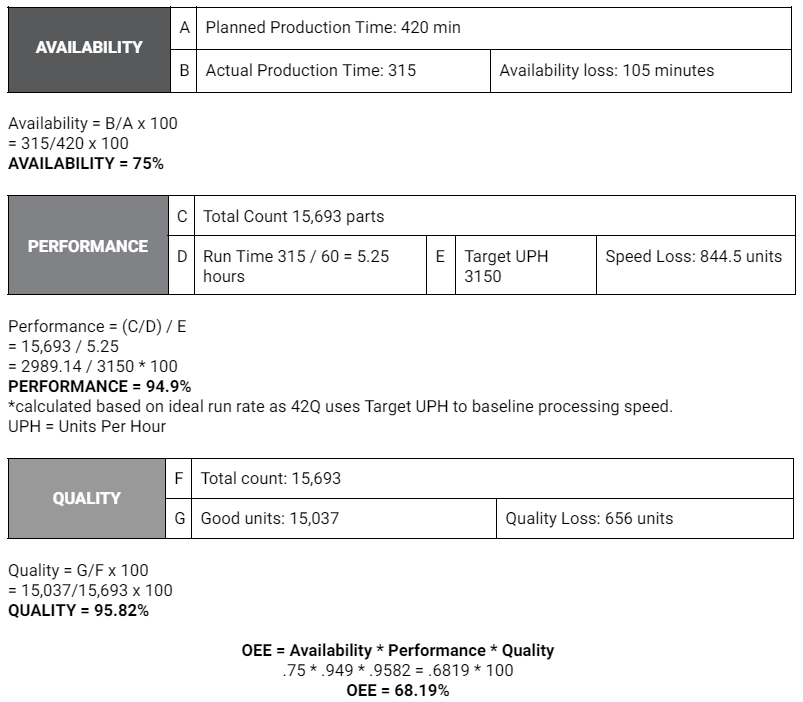

The benefits of an automated data collection

42Q’s OEE system allows manual or automatic data collection and interpretation. Although automated data collection might require some larger initial effort, it is a much more powerful and less error-prone strategy delivering more accurate and consistent information.

In the following table, you will find a comparison of computing OEE manually yourself versus using 42Q’s MES.

Top 5 Benefits

of Implementing CMMS

Author: Bobby Hanna | Date: February 02, 2022

Most maintenance teams have developed a reactive approach to breakdowns. Some of the most common maintenance issues include:

- Aging Equipment Prone To More Breakdowns

- Equipment Breakdowns Affecting Product Output

- High Maintenance Costs Cutting Into the Bottom-line

- Lack Of Consistency In Maintenance Procedures

- Data Stored In Multiple Locations, No System Of Record

Computerized Maintenance Management System (CMMS) provides a proactive solution to maintenance teams with centralized, standardized and streamlined maintenance operations.

Here are the Top 5 Benefits of CMMS

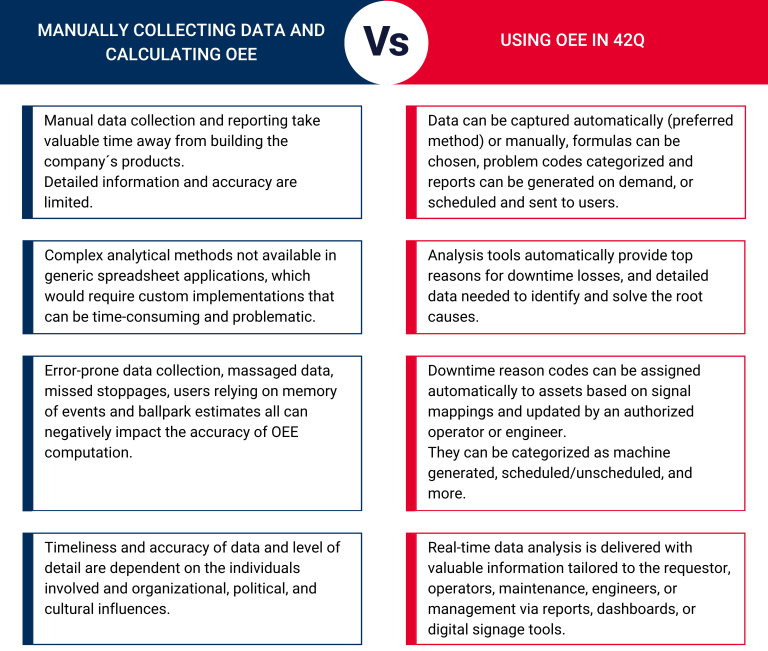

1. Reduced Downtime

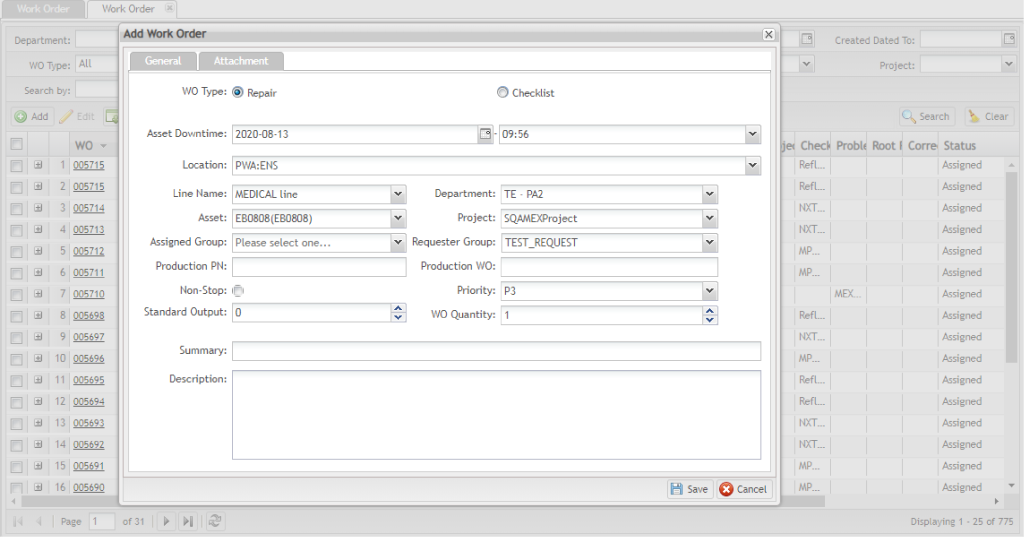

Preventive Maintenance is the best way to ensure that your manufacturing equipment runs smoothly and gives you the longest lifespan. CMMS allows you to schedule Preventive Maintenance so that work orders are automatically generated and assigned to the correct group within your organization. This allows you to conquer your maintenance backlog before it gets out of hand.

As equipment begins to age you start to see more issues with the reliability of these assets. It isn’t always financially possible to replace aging assets. CMMS allows you to collect, analyze and use an asset’s historical data to make informed decisions. This data can assist you in adjusting the maintenance schedule for aging assets to improve the reliability and prolong the lifespan.

2. Increased Efficiency

Taking maintenance and stoppage requests by email, phone, word of mouth or whiteboard forces your team to spend unnecessary time creating work orders and inputting data. CMMS eliminates these extra steps by automating the work request process. Employees can report downtime and submit work requests which will automatically be routed to the correct team within your organization. Work requests can also be set to escalate automatically to the correct personnel if the work is not completed within the configured time frame.

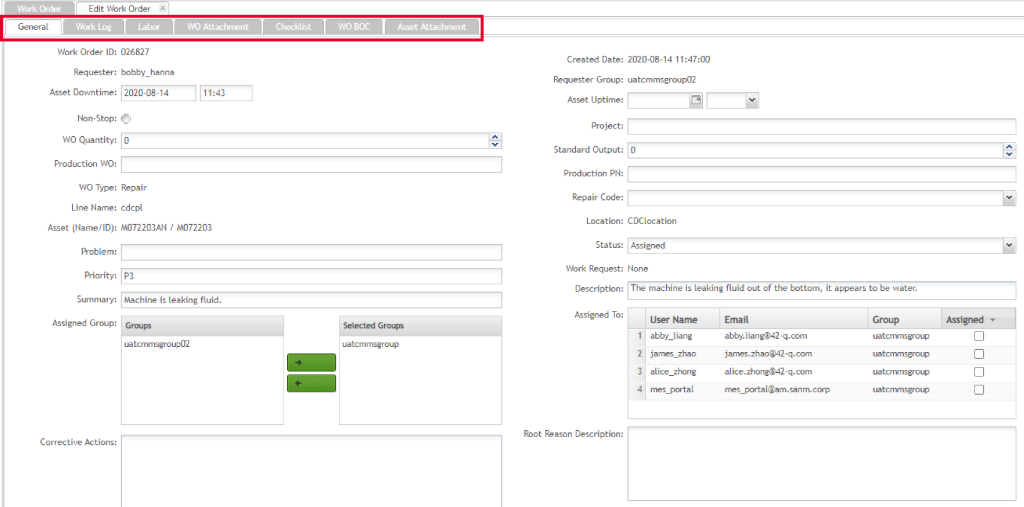

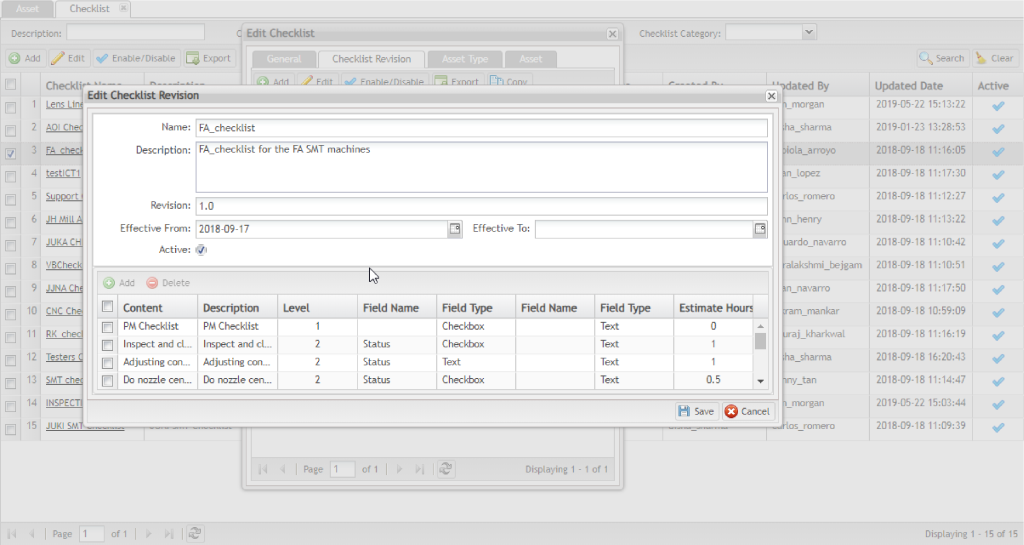

The lack of a central knowledge database means that technicians have to waste time tracking down people, flipping through paperwork and searching the internet for solutions to machine breakdowns. CMMS gives technicians quick and easy access to all the information necessary to complete a repair. Predefined checklists, images, videos, manuals and more can be added directly to a work order to assist the technician in getting the work done in less time.

3. Lower Maintenance Costs

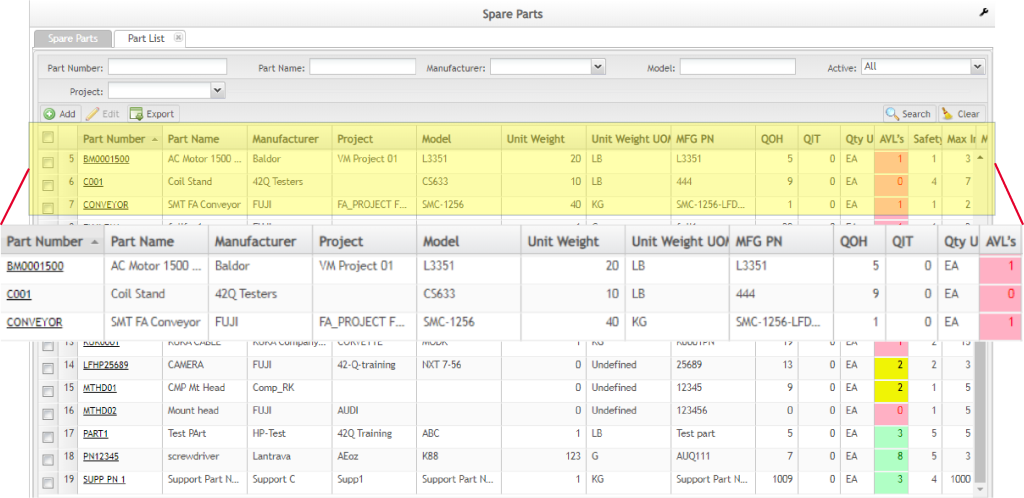

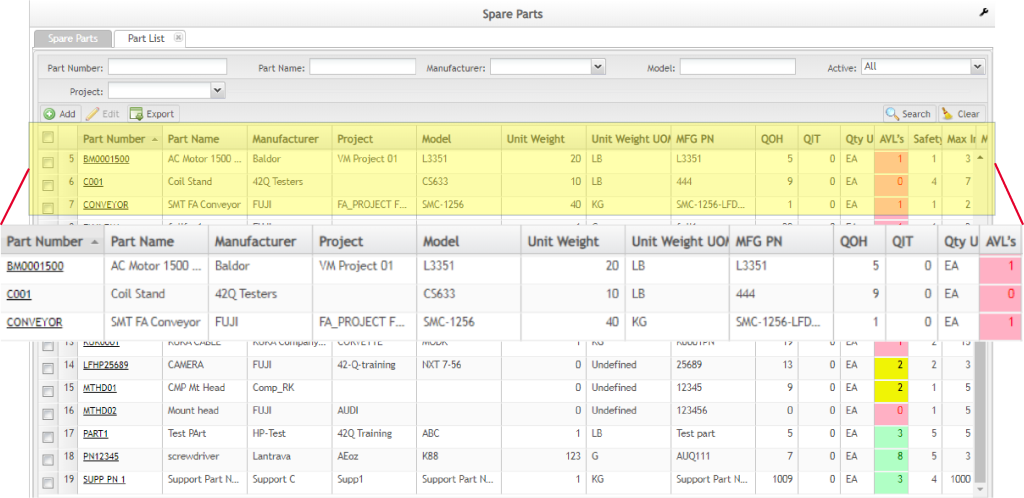

Not being in control of your inventory can greatly increase costs. Over purchasing of inventory adds unneeded additional costs. And if you don’t have the right parts on hand in the event of a breakdown it will result in additional downtime, rush shipping and risky stopgap methods, all of which are expensive. CMMS helps you track and organize your inventory to eliminate over or understocking. The Approved Vendor Lists (AVL’s) helps you mitigate risk by ensuring that you have multiple sources to obtain important parts.

When equipment goes down it brings lots of unwanted costs such as downtime, parts and labor. These additional costs can begin to stack up very quickly. CMMS gives you the ability to ensure that Preventative Maintenance is done correctly according to the manufacturer’s specifications. Preventative Maintenance is the best way to resolve issues proactively by finding small issues before they become major problems.

4. Greater Compliance

A lack of standardization can lead to important maintenance tasks getting missed or skipped which can lead to unwanted downtime. CMMS gives you the ability to build predefined maintenance checklists. This ensures that all technicians follow best practices and get the job done as quickly and as accurate as possible.

Audits can be difficult to pass without the correct documentation and records. Failing an audit can bring huge costs and headaches. CMMS gives you the ability to produce all necessary maintenance records by asset or time frame. Inventory records and locations also simplify producing the necessary information for audits.

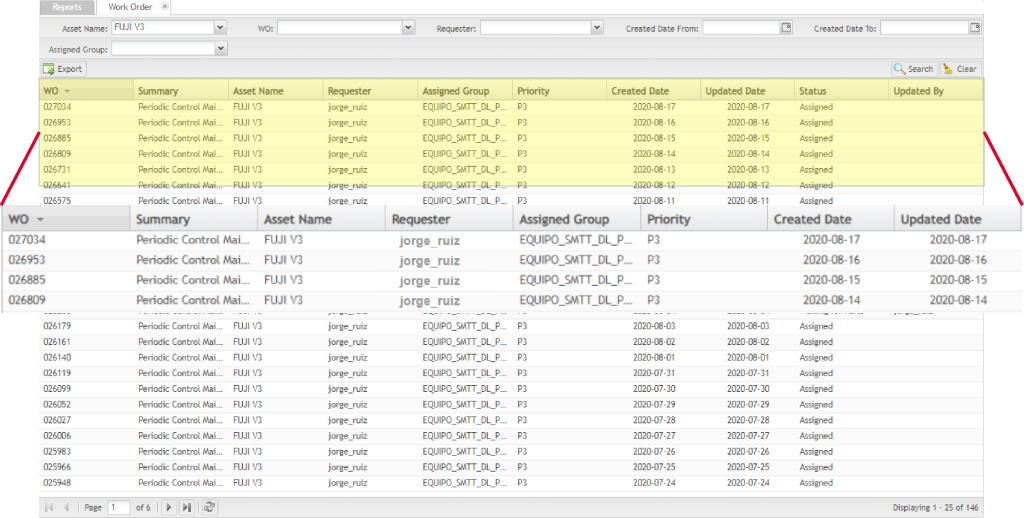

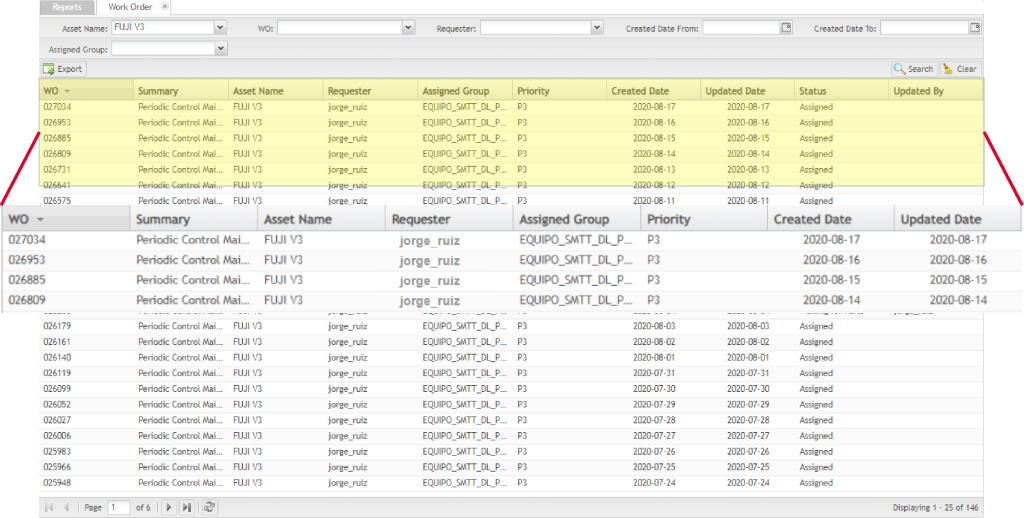

5. Data Collection

Not having visibility into the status of your work orders is one of the main ways that your backlog starts to grow. If the right people don’t have visibility into work orders, it can lead to more downtime and uninformed decision making. CMMS allows you to have real-time updates into the status of work orders as well as the status of the equipment on the manufacturing floor.

Maintenance KPI’s help you identify chronic issues with your machinery and make informed decisions about equipment issues. Trying to compile these reports by hand can be time consuming and lead to mistakes. CMMS allows you to collect data and view Maintenance KPI data easily in pre-built report templates. This allows you to quickly identify trends, recurring problems and more.

42Q Xchange

Author: Keith Fuqua | Date: January 24, 2022

Introducing 42Q Xchange. What is 42Q Xchange? 42Q Xchange is a set of APIs designed to allow connectivity between the customers’ ERP systems and 42Q, providing critical integration in their overall digital factory implementation. Traditionally, ERP integration with an MES system requires an “adapter”, a set of code which would be installed and deployed in the customer’s ERP system. An adapter provides ERP-specific code to process manufacturing-related transactions, integrates with the MES using APIs, and provides custom developed screens for monitoring, error handling and other MES-related functions. While an adapter is desirable from a connectivity standpoint, there are a substantial number of different ERP systems in use in various industries. Developing adapters for a wide variety of ERP systems is not only expensive in terms of cost, development, and overall support. It is also extremely difficult to be knowledgeable in how all ERP systems work. Additionally, some customers are understandably nervous about third party systems installing code into their ERP systems.

The approach of 42Q Xchange is to provide a standard set of secure APIs that provide all the key capabilities of an ERP adapter, without the need to develop, maintain, and deploy code into a customer’s ERP system. 42Q Xchange even allows users to create ERP style transactions, without having an ERP. This is accomplished through easy to understand templates developed in Microsoft Excel and LibreOffice Calc. A user can easily populate a template, providing all the information for a work order, BOM, and other manufacturing information, easily creating ERP work orders in a configured 42Q environment.

42Q Xchange functions in a publish/subscribe model. APIs can be called to trigger creates, updates or other transactions in a configured 42Q environment. 42Q in turn will publish common transactions that would be consumed by an ERP, such as Material Issues, Work In Progress movements, and completions. A user subscribes to the published transactions. The user can then process the published transactions in their system, thereby updating the ERP system.

One of the key advantages of 42Q Xchange is the time and effort for deployment. Because a set of code is not being installed into an ERP system, this eliminates a lot of the time, effort, security concerns, and approvals typically required to get an adapter deployed into a customer’s ERP system.

The Relevance of

OEE and TEEP For

Manufacturers Today

Author: Bobby Hanna | Date: November 24, 2021

Overall Equipment Effectiveness (OEE) is a measure of performance in the domain of manufacturing. It encompasses the maturity level of the shop floor from a standpoint of productivity, quality and availability of the assets to ensure operational efficiency and in turn address business results. OEE is measured as the product of productivity, quality and availability and is expressed as a percentage.

This measure truly indicates the KPI of a manufacturing process. OEE gives a true reflection of how a manufacturing line is performing and hence this metric becomes a primary source of data to drive manufacturing excellence.

Another measure of performance is Total Effective Equipment Performance (TEEP), which in addition to the parameters of OEE, takes into account the utilisation aspect of the manufacturing line. TEEP is measured as the product of productivity x quality x availability x utility expressed as a percentage.

A real-time data acquisition of these parameters will help the operational teams to gain an insight into how their lines are performing. Since manufacturing lines are performing tasks which are time deterministic, data acquisition at source becomes a primary challenge. Real-time data visibility will enable operations team to take data based decisions within the stipulated takt time to ensure seamless flow of downstream processes

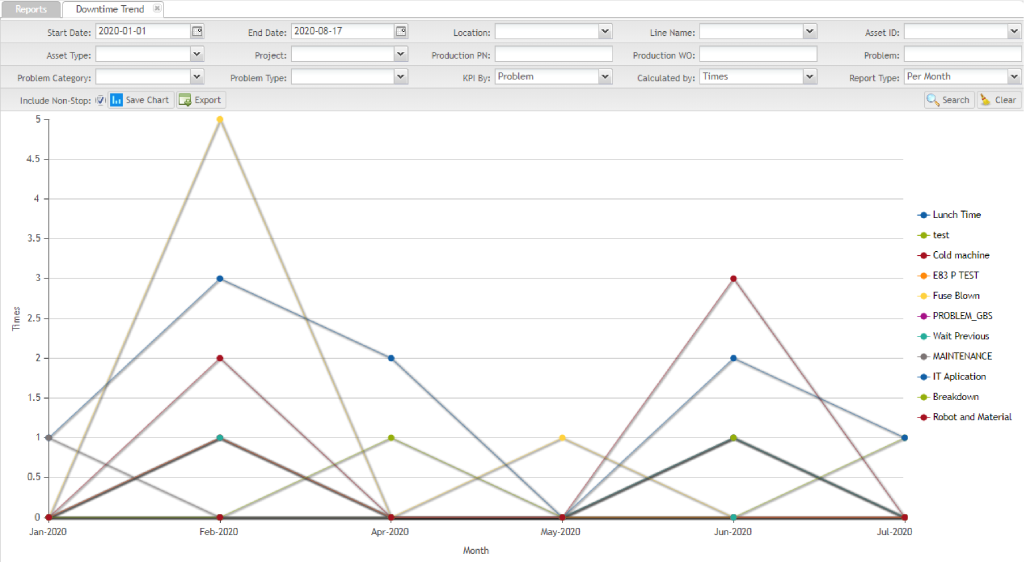

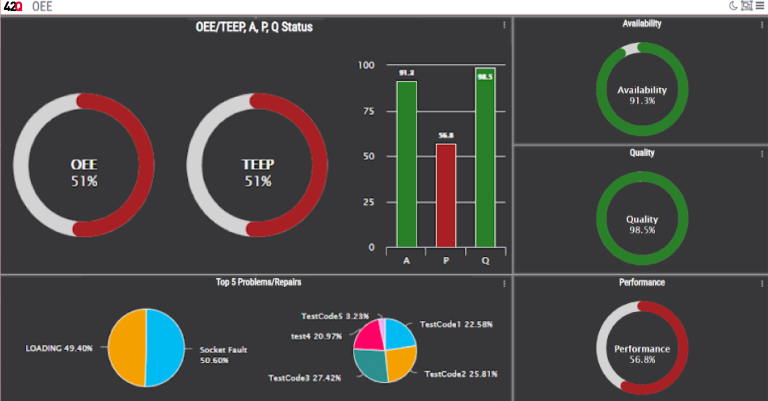

42Q functionalities encompasses these aspects and gives a holistic view of how each parameter is behaving and gives an insight through descriptive analytics. 42Q gives you a single location for gathering all the necessary information for OEE & TEEP calculations. Information such as Throughput, Yield, Cycle Time, Machine Up/Down Time, Downtime Root Cause, etc. can then be broken down to the work shift and operator level as shown below.

The default reports include the following:

- OEE & TEEP Dashboard

- Downtime Root Cause Analysis

- Downtime Trend Analysis

- OEE Trend Analysis

We have the capability to acquire these data sets and portray them in a way which truly reflects time based behavior of the manufacturing line. In 42Q, one has access to reports and dashboards on the real-time OEE & TEEP statistics. This fully customizable panel gives you the ability to monitor the current manufacturing line readings as compared to expected target results. As a result, 42Q allows plant managers to quickly troubleshoot critical problems in real-time.

Furthermore, 42Q Live enables you to see the real-time status of critical stations on your manufacturing floor. This allows you to send Alerts and Notifications based on threshold settings.