What is a Computerized Maintenance Management System (CMMS) in MES?

What is a Computerized Maintenance Management System (CMMS) in MES?

Equipment reliability is one of the most important factors in maintaining an efficient manufacturing operation.

A computerized maintenance management system (CMMS) ensures that maintenance activities are planned, tracked, and executed in a way that minimizes disruptions and maximizes uptime. Manufacturing facilities depend on these systems to automate work orders, manage asset lifecycles, and integrate maintenance workflows with production schedules.

The ability to monitor equipment health in real time and schedule proactive maintenance helps manufacturers prevent costly breakdowns and extend machine lifespan. A CMMS in manufacturing reduces maintenance costs, improves compliance, and enhances workforce efficiency. When integrated with a manufacturing execution system (MES), it creates a seamless connection between production and maintenance teams, ensuring that equipment remains operational without impacting output.

Key Features of CMMS Software in MES

A computerized maintenance management system (CMMS) plays a vital role in manufacturing execution systems (MES) by ensuring seamless maintenance operations, reducing equipment failures, and supporting continuous production. The right CMMS software provides essential tools to automate maintenance workflows, track asset performance, and optimize resource management. These features improve plant efficiency, extend machine lifespan, and help manufacturers meet compliance requirements.

- Automated Work Order Management: Generates, assigns, and tracks maintenance tasks, ensuring technicians receive real-time alerts for inspections and repairs. Automated workflows reduce manual scheduling errors, improve technician efficiency, and promptly address high-priority repairs.

- Preventive and Predictive Maintenance: Uses historical performance data, sensor readings, and condition-based monitoring to schedule maintenance activities before failures occur. This proactive approach minimizes costly unplanned downtime and prevents extensive damage to equipment.

- Asset Tracking and Equipment Management: Maintains a centralized database for machinery, tools, and infrastructure, allowing manufacturers to track usage, maintenance history, and depreciation. Keeping accurate records improves asset utilization and helps maintenance teams make informed repair or replacement decisions.

- Spare Parts and Inventory Control: Monitors stock levels, tracks usage patterns, and automates reordering processes to prevent supply shortages. Having the right spare parts available reduces repair wait times, ensuring minimal disruption to production.

- Failure Analysis and Root Cause Reporting: Identifies recurring issues by analyzing failure patterns and maintenance records. Data-driven insights help maintenance teams implement long-term solutions that reduce repeated breakdowns and lower repair costs.

- Compliance and Audit Support: Tracks maintenance records, inspection reports, and calibration logs to meet industry-specific regulatory requirements. Built-in compliance tools streamline audit preparation, ensuring manufacturers have accurate documentation readily available.

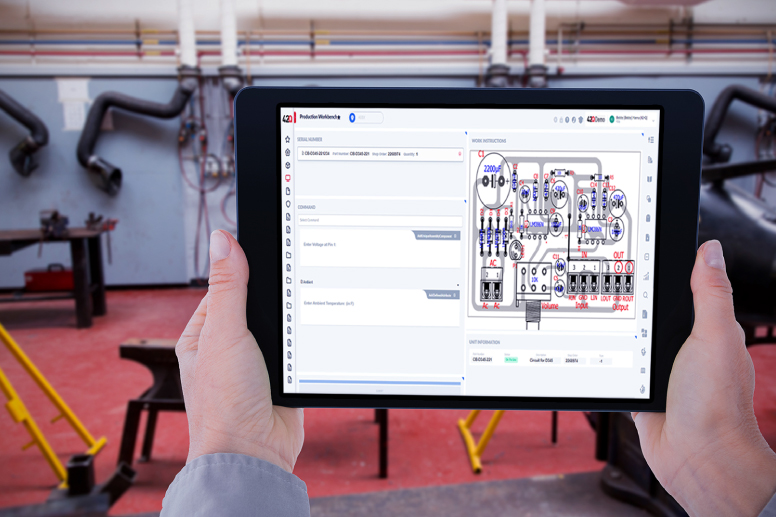

- Mobile Access for Maintenance Teams: Provides technicians with mobile-friendly platforms to receive work orders, log maintenance activities, and update asset information in real-time. Mobile CMMS solutions improve response times and reduce communication delays.

- IoT and Sensor-Based Monitoring: Integrates with connected devices and industrial sensors to monitor equipment performance in real-time. Automated alerts notify maintenance teams of irregularities, predictive maintenance that prevents equipment failures.

- Customizable Dashboards and Reporting: Offers data visualization tools that help plant managers analyze key performance indicators (KPIs), track maintenance efficiency, and improve resource allocation. Custom reports provide insights into work order completion rates, asset reliability, and maintenance costs.

- Integration with MES and ERP Systems: Ensures seamless data exchange between maintenance, production, and business operations. Connecting CMMS software with MES and ERP platforms allows manufacturers to synchronize maintenance activities with production schedules, improving overall workflow efficiency.

A CMMS in manufacturing provides essential tools to streamline maintenance operations, prevent equipment failures, and improve cost control. These features help manufacturers optimize asset performance, minimize production disruptions, and maintain compliance with regulatory standards.

The Role of CMMS in Manufacturing

A CMMS in manufacturing serves as the foundation for effective equipment maintenance, helping facilities minimize disruptions and optimize productivity. Production lines rely on machinery operating at peak efficiency, and any unexpected breakdown can result in costly delays. A computerized maintenance management system ensures that all maintenance activities are scheduled, tracked, and executed in a way that maximizes uptime while keeping repair costs under control.

Manufacturers use a CMMS to implement proactive maintenance strategies that reduce the likelihood of unplanned downtime. Equipment sensors and historical performance data allow teams to anticipate failures and take corrective action before they impact production. Maintenance workflows are automated to assign tasks based on priority, resource availability, and machine usage patterns. This level of coordination helps manufacturing plants operate with fewer disruptions and lower operational risks.

Compliance with industry regulations is another critical function of a CMMS in MES. Manufacturing industries such as medical devices, automotive, and aerospace require meticulous tracking of maintenance records, calibration schedules, and component replacements. A CMMS software simplifies compliance efforts by documenting all maintenance activities and ensuring audit trails remain accurate and current.

Benefits of Manufacturing CMMS

A computerized maintenance management system (CMMS) improves manufacturing efficiency by automating maintenance workflows, tracking asset performance, and reducing equipment downtime. In an industry where operational delays lead to significant costs, a well-implemented CMMS in manufacturing ensures that maintenance teams work proactively rather than reacting to unexpected failures. The following benefits help manufacturers reduce expenses, optimize resource allocation, and improve production efficiency.

- Reduced Equipment Downtime: Scheduled maintenance tasks and predictive analytics allow maintenance teams to detect potential failures before they impact production. This proactive approach ensures equipment remains operational, minimizing disruptions to manufacturing schedules and preventing revenue loss.

- Lower Maintenance and Repair Costs: Optimized maintenance schedules prevent excessive wear and tear, reducing the need for costly emergency repairs. A CMMS in MES also helps allocate maintenance resources efficiently, preventing unnecessary labor and equipment expenditures.

- Extended Asset Lifespan: Routine inspections, timely repairs, and condition-based maintenance strategies help extend the life of machinery and production equipment. A maintenance approach reduces premature replacements, protecting capital investments.

- Improved Regulatory Compliance: Manufacturing industries, including medical devices and aerospace, require strict adherence to regulatory maintenance and safety standards. CMMS software automates documentation, ensuring that maintenance records, calibration logs, and audit trails remain accurate and readily accessible.

- Increased Workforce Efficiency: Automated work orders eliminate manual scheduling errors, ensuring technicians receive precise instructions based on equipment priorities. Mobile access to maintenance records allows teams to complete tasks more efficiently and respond to urgent repairs without delays.

- Optimized Spare Parts and Inventory Management: Automated stock level tracking ensures critical spare parts remain available. A manufacturing CMMS prevents overstocking while reducing risks associated with parts shortages, ensuring that repairs are completed on time.

- Better Equipment Performance Monitoring: IoT sensors and MES data provide real-time insights into machine conditions. Maintenance teams can rely on data-driven triggers for servicing, reducing reliance on static maintenance schedules that may not align with equipment needs.

- Enhanced Data Analytics and Reporting: Custom reports and dashboards help manufacturers track maintenance costs, technician productivity, and asset reliability. Data-driven insights support better long-term maintenance planning and strategic rationale.

- More substantial Safety and Risk Management: Regular maintenance inspections reduce the likelihood of equipment malfunctions that could pose safety hazards to employees. A CMMS software ensures that machinery remains in optimal working condition, lowering the risk of workplace incidents.

- Seamless Integration with Production Workflows: A CMMS in MES connects maintenance activities with production schedules, ensuring that planned maintenance does not interfere with critical manufacturing processes. Coordinated workflows improve efficiency without sacrificing output.

A CMMS in manufacturing ensures that production facilities remain efficient, safe, and cost-effective. Manufacturers improve asset reliability by centralizing maintenance operations and automating workflows, reducing unexpected expenses and compliance risks.

Integrating CMMS with MES

A computerized maintenance management system (CMMS) becomes more effective when integrated with a manufacturing execution system (MES). This connection allows manufacturers to align maintenance activities with production schedules, reducing unplanned downtime and improving overall operational efficiency. An integrated system ensures real-time asset performance monitoring, providing maintenance teams with data-driven insights to schedule preventive maintenance without disrupting manufacturing processes.

Seamless integration between CMMS software and an MES improves communication between maintenance and production teams. Equipment health data flows directly into the CMMS, allowing maintenance teams to prioritize repairs based on asset conditions rather than relying solely on time-based schedules. This coordination reduces production stoppages and prevents unnecessary maintenance activities, optimizing machine uptime and resource allocation.

Real-Time Equipment Monitoring

Machine performance data captured by IoT sensors, programmable logic controllers (PLCs), and MES platforms feed directly into the CMMS, allowing maintenance teams to assess asset health in real-time. If a piece of equipment starts showing irregular patterns, automated alerts trigger maintenance requests before failures occur. This prevents unexpected breakdowns while reducing unnecessary preventive maintenance, ensuring resources are used efficiently.

Automated Work Order Scheduling

An integrated system generates work orders based on machine conditions, production requirements, and technician availability. Maintenance tasks are scheduled in coordination with manufacturing workflows, ensuring that planned servicing does not disrupt critical operations. This approach eliminates the inefficiencies of manual scheduling and ensures that equipment receives service at the optimal time.

Enhanced Data Accuracy and Reporting

Manual data entry often leads to inconsistencies and errors that compromise maintenance efficiency. A CMMS in MES eliminates these challenges by automatically recording maintenance logs, repair history, and asset performance data. Accurate reporting gives maintenance managers insights into failure trends, labor efficiency, and cost-saving opportunities, improving long-term maintenance planning.

Optimized Spare Parts and Inventory Control

Connecting CMMS software with an MES directly links maintenance needs and spare parts inventory. Automatic inventory tracking ensures that necessary components are available before a maintenance task begins, reducing delays caused by missing parts. This also prevents overstocking, reducing inventory holding costs while providing critical supplies are always on hand.

Better Compliance and Audit Readiness

Manufacturers in regulated industries must maintain accurate maintenance records for compliance audits. An integrated CMMS in manufacturing streamlines this process by documenting all inspections, repairs, and calibrations in a centralized system. This improves audit readiness and helps manufacturing facilities meet regulatory standards without the burden of manual documentation.

A CMMS integrated with MES provides manufacturers with a connected maintenance strategy that enhances efficiency, reduces downtime, and extends asset lifespan. The ability to track machine health, automate scheduling, and optimize inventory ensures that maintenance operations align with production goals, improving overall plant performance.

Choosing the Right CMMS Software for MES

Selecting a computerized maintenance management system that integrates effectively with an MES requires careful evaluation of key factors that impact operational efficiency, scalability, and cost-effectiveness. Manufacturing operations rely on a CMMS that automates maintenance workflows and aligns with existing production processes.

Compatibility with MES software is essential for seamless data exchange between maintenance and production teams. A system that integrates with IoT devices, machine sensors, and enterprise resource planning (ERP) platforms ensures real-time equipment monitoring and accurate maintenance tracking. Cloud-based deployment options offer flexibility by reducing on-site infrastructure costs while providing secure remote access to maintenance records.

User-friendly interfaces and mobile accessibility improve adoption rates among maintenance teams. A well-designed CMMS allows technicians to access work orders, submit reports, and update asset records from any location. Customization options further enhance usability, allowing manufacturers to tailor features such as automated scheduling, compliance tracking, and spare parts management to fit their specific needs.

Scalability is another important factor when selecting a CMMS in manufacturing. A system that supports multiple facilities, production lines, and asset categories ensures long-term usability as business operations expand. Generating detailed reports and analytics also enhances maintenance planning, helping manufacturers optimize performance and reduce operational risks.

EAM vs CMMS: Key Differences

The main difference between an enterprise asset management (EAM) system and a computerized maintenance management system (CMMS) lies in their scope and functionality. A CMMS focuses on maintenance-related tasks, while an EAM provides a broader approach to asset management, covering the entire lifecycle of equipment from procurement to disposal.

| Feature | CMMS | EAM |

| Primary Focus | Maintenance scheduling and tracking | Full asset lifecycle management |

| Scope | Equipment maintenance and repairs | Procurement, maintenance, and asset utilization |

| Integration | Works with MES and maintenance teams | Connects with ERP, MES, and financial systems |

| Asset Lifecycle | Limited to the operational phase | Covers acquisition, operation, and decommissioning |

| Inventory Management | Tracks spare parts for maintenance | Manages asset-related inventory and procurement |

| Compliance Support | Ensures regulatory maintenance tracking | Covers audits, compliance reporting, and documentation |

A CMMS in manufacturing is primarily designed to manage maintenance operations, focusing on scheduling, work orders, and spare parts tracking. It helps manufacturers prevent downtime and maintain regulatory compliance through detailed maintenance logs and automated workflows.

An EAM system takes a more comprehensive approach, tracking assets throughout their lifecycle, from initial acquisition to retirement. This system integrates with financial and procurement modules, making it a better choice for manufacturers that require enterprise-wide asset management.

Future Trends in CMMS for Manufacturing

Advancements in computerized maintenance management system (CMMS) software continue to improve manufacturers' management of maintenance operations, reduce downtime, and optimize asset performance. As manufacturing facilities adopt more innovative technologies, CMMS in MES solutions incorporate automation, real-time analytics, and predictive capabilities to improve efficiency. The following trends are shaping the future of CMMS software in manufacturing.

- AI-Powered Predictive Maintenance: Artificial intelligence (AI) analyzes machine performance data to identify patterns that indicate potential failures. Instead of relying on fixed maintenance schedules, AI-driven insights help maintenance teams anticipate issues before they lead to breakdowns, improving equipment reliability and reducing repair costs.

- IoT-Connected Maintenance Systems: Industrial IoT (IIoT) devices collect real-time sensor data from machines, continuously monitoring temperature, vibration, and energy consumption. A CMMS in manufacturing processes this data and generates automated alerts when equipment conditions deviate from normal operating ranges, allowing maintenance teams to act before failures occur.

- Cloud-Based CMMS Deployment: Cloud-based CMMS software allows manufacturers to manage maintenance operations without requiring extensive on-site infrastructure. Cloud solutions offer better accessibility for maintenance teams, secure data storage, automatic updates, and the ability to scale across multiple facilities without expensive hardware investments.

- Augmented Reality (AR) for Maintenance Support: AR technology assists technicians by overlaying real-time visual instructions onto equipment during inspections and repairs. This helps reduce downtime, minimize human errors, and improve training for new maintenance personnel, ensuring tasks are performed correctly without delays.

- Mobile CMMS Applications for On-the-Go Maintenance: Maintenance teams benefit from mobile-friendly CMMS software that provides instant access to work orders, asset records, and real-time machine data. Mobile solutions improve response times by allowing technicians to diagnose and resolve issues without being tied to a desktop interface.

- Automated Workflows and AI Chatbots: AI-powered virtual assistants help maintenance teams schedule and manage tasks by automating routine processes such as work order creation and equipment status updates. These tools reduce administrative burdens, allowing technicians to focus on critical maintenance tasks instead of manual data entry.

- Integration with ERP, MES, and Supply Chain Systems: Future CMMS solutions are improving integration with manufacturing execution systems (MES), enterprise resource planning (ERP), and supply chain platforms. This parallel approach ensures maintenance planning aligns with production goals, inventory management, and procurement schedules, reducing downtime caused by equipment failures or spare part shortages.

- Sustainability-Focused Maintenance Strategies: Manufacturers prioritize energy-efficient and sustainable maintenance practices to reduce waste and lower operational costs. A CMMS and a capable MES can support these initiatives by tracking energy usage, optimizing maintenance schedules, and ensuring compliance with fit regulations.

- Automated Compliance and Safety Audits: Compliance tracking tools within CMMS software simplify audits by maintaining digital records of inspections, certifications, and regulatory maintenance requirements. Automation reduces non-compliance risk while ensuring that all equipment remains appropriately working.

Advancements in CMMS technology are reshaping maintenance strategies by improving efficiency, increasing automation, and reducing costs. Combining AI, IoT, and real-time data analytics ensures manufacturers can optimize maintenance operations while keeping production lines running smoothly.

Manufacturers worldwide are adopting digital solutions to improve efficiency, precision, and scalability. At 42Q, we combine decades of manufacturing expertise with cutting-edge technology to deliver smart connected manufacturing. Our flexible, cloud-native MES platform enhances visibility, streamlines operations, and accelerates digital transformation. Discover how our solutions can empower your factory to achieve its full potential.

Key Takeaways

- A computerized maintenance management system (CMMS) automates maintenance tracking, work order scheduling, and asset management, reducing downtime in manufacturing.

- Integrating CMMS software with an MES ensures seamless coordination between maintenance and production, improving efficiency and reducing operational risks.

- Predictive maintenance powered by IoT and AI helps manufacturers schedule repairs based on real-time equipment data, preventing costly failures.

- Compliance tracking within a CMMS in manufacturing simplifies audits by maintaining digital records of maintenance activities, inspections, and regulatory requirements.

- Cloud-based CMMS solutions provide manufacturers with remote access, automated updates, and scalable deployment, making maintenance operations more efficient and cost-effective.

FAQs

A computerized maintenance management system (CMMS) is a software tool that automates maintenance tracking, schedules repairs, and manages asset lifecycles. It helps manufacturers reduce downtime, improve efficiency, and optimize maintenance resources.

A CMMS in MES connects maintenance activities with production schedules, ensuring real-time equipment monitoring and automated work order management. This integration helps maintenance teams prevent disruptions while optimizing machine uptime.

Industries such as automotive, aerospace, medical devices, and consumer electronics rely on CMMS software to maintain regulatory compliance, improve asset reliability, and reduce maintenance costs. Any industry that depends on continuous production benefits from a CMMS.

Predictive maintenance in a CMMS in manufacturing uses IoT sensors and historical performance data to identify early signs of wear or failure. Maintenance tasks are scheduled based on actual asset conditions, reducing unnecessary servicing and preventing unexpected breakdowns.

A manufacturing CMMS lowers maintenance costs by preventing equipment failures, reducing emergency repairs, and optimizing spare parts inventory. Automated maintenance scheduling ensures resources are used efficiently, helping manufacturers control expenses while improving productivity.

How 42Q is Shaping the Next Era of Manufacturing

Building a Smarter, Greener Future

How 42Q is Shaping the Next Era of Manufacturing

As we approach Hannover Messe, the manufacturing world is buzzing with anticipation. It’s a time to reflect on where the industry is headed and how we can tackle the challenges of tomorrow. At 42Q, we’ve spent the past year working closely with manufacturers to address two of the most pressing issues facing the industry today: sustainability and the intelligent use of technology.

This isn’t about chasing trends, it’s about solving real problems. Manufacturers are under pressure to do more with less: less waste, less downtime, and less complexity. At the same time, they need to stay competitive in a rapidly changing landscape. That’s where we come in. Over the past 12 months, we’ve made significant strides in helping manufacturers achieve operational excellence while building a foundation for a more sustainable future.

Sustainability: It’s a Goal, and a Journey that requires Focus

Let’s be honest… sustainability isn’t just a nice-to-have anymore. It’s a business driver. But for many manufacturers, the path to sustainability isn’t always clear. How do you reduce waste without sacrificing efficiency? How do you optimize resource use without overhauling your entire operation? These are the questions we’ve been working to answer.

Data as the Foundation for Sustainable Manufacturing

At 42Q, we believe that sustainability starts with visibility. You can’t improve what you can’t measure. That’s why we’ve focused on giving manufacturers the tools to see their operations clearly—from energy use to material waste to equipment performance.

Our Connected Manufacturing platform, built on AWS, pulls data from across the production floor and beyond, giving manufacturers a unified view of their operations. This isn’t just about collecting data; it’s about turning that data into actionable insights. For example, by analyzing cycle times and defect rates, manufacturers can pinpoint inefficiencies and reduce waste. By monitoring energy consumption, they can identify opportunities to cut costs and lower their environmental impact.

Modular Solutions for Sustainable Growth

Another way we’re helping manufacturers build sustainability into their operations is through our composable MES architecture. Traditional manufacturing systems often come with a lot of unnecessary baggage—features you don’t need, complexity you don’t want, and costs you can’t justify. Our modular approach lets manufacturers build a system that’s tailored to their specific needs, without the bloat.

This isn’t just good for the bottom line; it’s good for the planet. By only using what you need, you reduce waste—both in terms of resources and energy. And because the system is designed to grow with you, it ensures that sustainability is built into your operations from the ground up.

AI in Manufacturing: Not Just the Hype, But Real Value

There’s a lot of talk about AI in manufacturing, and frankly, a lot of it is overhyped. But when applied thoughtfully, AI can deliver real value. Over the past year, we’ve been working to integrate AI into our platform in ways that actually make a difference for manufacturers.

Arthur: Making AI Work for You

One of our proudest accomplishments this year has been the rollout of Arthur, our AI-powered assistant. Arthur is a practical tool designed to make life easier for manufacturers. Think of it as a knowledgeable colleague who’s always there to help. Need to troubleshoot a machine? Arthur can guide you through it. Looking for real-time production data? Arthur can pull it up in seconds.

What makes Arthur truly valuable is its ability to streamline workflows and reduce downtime. By providing instant access to critical information, Arthur helps manufacturers make faster, smarter decisions. And because it’s powered by Amazon Bedrock, it’s constantly learning and improving, ensuring that it stays relevant as your needs evolve.

AI Beyond the Hype: Predictive Maintenance and Quality Control

Beyond Arthur, we’re also exploring how AI can be used to tackle some of the biggest pain points in manufacturing. For example, predictive maintenance is a game changer for reducing downtime and extending the life of equipment. By analyzing data from sensors and historical performance, AI can predict when a machine is likely to fail—before it happens. This not only saves time and money but also reduces the waste associated with unexpected breakdowns.

Similarly, AI can play a key role in quality control. By analyzing production data in real time, AI can detect defects early in the process, reducing waste and ensuring that only high-quality products make it to market. These aren’t futuristic ideas—they’re practical applications of AI that are delivering real results today.

What We’ve Achieved: A Year of Progress

Looking back over the past 12 months, we’re proud of what we’ve accomplished. Here are a few highlights:

- Connected Manufacturing: We’ve helped manufacturers gain a unified view of their operations, enabling them to make smarter, more sustainable decisions.

- Arthur: Our AI-powered assistant has become an indispensable tool for manufacturers, streamlining workflows and reducing downtime.

- Composable MES: Our modular approach has given manufacturers the flexibility they need to build systems that grow with them, without unnecessary waste or complexity.

- Strategic Partnerships: We’ve strengthened our collaborations with industry leaders, ensuring that our customers have access to the best tools and expertise available.

Looking Ahead: What’s Next for 42Q?

As we head into Hannover Messe, we’re more committed than ever to helping manufacturers navigate the challenges of tomorrow. Sustainability and AI will continue to be key focus areas, but we’re also looking at new ways to drive efficiency, reduce complexity, and empower manufacturers to do their best work.

We’re excited to share our latest innovations at the show, and we look forward to connecting with manufacturers who are ready to take their operations to the next level. Because at the end of the day, our goal is to help manufacturers build a smarter, greener, and more efficient future.

The Future of Automotive Manufacturing and MES

The Future of Automotive Manufacturing and MES

Manufacturing Execution Systems (MES) are forming automotive production, improving efficiency, quality, and traceability across the factory floor.

As manufacturing complexity increases, companies must manage production schedules, reduce waste, and meet regulatory requirements while maintaining cost control. MES bridges the gap between enterprise resource planning (ERP) systems and factory operations, providing real-time data, automation, and process optimization. Automotive manufacturers adopting MES gain improved visibility, streamlined workflows, and enhanced production capabilities, ensuring they meet the growing industry with greater precision and reliability.

What is Automotive Manufacturing in MES?

Automotive manufacturing involves complex processes that form raw materials into fully functional vehicles. This industry relies on precision engineering, supply chain coordination, and quality control to ensure production efficiency and product reliability. Manufacturers seek solutions to enhance operations while reducing costs and production timelines as technology advances.

A Manufacturing Execution System (MES) plays an essential role in modern automotive production by bridging the gap between enterprise resource planning (ERP) systems and factory floor operations. MES provides real-time monitoring, data collection, and process automation, helping manufacturers optimize production workflows, improve traceability, and ensure compliance with industry regulations. With increasing efficiency and scalability, MES solutions are now essential for manufacturers looking to streamline operations and meet customer expectations.

Benefits of MES in Automotive Manufacturing

Automobile manufacturers must maintain high production standards while adapting to shifting market conditions. MES improves factory operations by providing digital tools that track performance, optimize workflows, and enhance overall productivity. These benefits help manufacturers lower costs, reduce errors, and maintain consistency throughout production.

- Production efficiency: MES automates data collection, reducing manual errors and ensuring accurate process tracking. This improves workflow efficiency and minimizes production downtime.

- Quality control: Real-time monitoring allows manufacturers to detect and address defects before they escalate, improving product quality and reducing waste.

- Traceability and compliance: MES provides full product traceability, recording each manufacturing process step. This helps meet regulatory requirements and improves audit readiness.

- Workforce optimization: Operators receive digital work instructions, reducing training time and enhancing worker efficiency on the factory floor.

- Supply chain visibility: MES integrates with ERP and other business systems, providing better visibility into material availability and production schedules. This improves planning and reduces delays.

- Cost reduction: Process automation and predictive maintenance reduce material waste, energy consumption, and unplanned downtime, lowering production costs.

- Scalability: MES supports multi-plant operations, allowing manufacturers to standardize processes across multiple facilities while maintaining centralized control.

Manufacturers implementing MES gain better control over production while improving agility in responding to operational challenges. These advantages make MES an essential tool for automotive companies looking to improve efficiency and maintain high-quality manufacturing standards.

Examples of MES in Automotive Manufacturing

Manufacturers rely on MES to improve efficiency, maintain product quality, and meet production goals. The system integrates with factory operations to support automation, provide real-time insights, and improve traceability. These capabilities address specific challenges in automotive manufacturing, ensuring consistent results across production lines.

1. Digital Work Instructions for Assembly Processes

Automotive production involves assembling thousands of components with precision. MES provides digital work instructions, guiding operators through each step with real-time updates. This reduces errors, minimizes rework, and ensures each vehicle meets quality standards. Operators can also receive automated alerts for process deviations, preventing defects before they affect production.

2. Production Monitoring and Performance Analytics

Factory performance depends on accurate data collection and analysis. MES tracks production rates, machine uptime, and operator efficiency, providing manufacturers with real-time insights into performance metrics. These analytics help identify bottlenecks and inefficiencies, allowing process adjustments that improve production speed and output quality.

3. Traceability for Compliance and Quality Assurance

Automotive manufacturing requires complete traceability of parts and materials to meet industry regulations. MES records each step of production, capturing data on material origins, assembly processes, and quality checks. If a defect occurs, manufacturers can trace the issue back to its source and take corrective action, reducing the risk of recalls and compliance violations.

4. Automated Inventory and Supply Chain Integration

Supply chain coordination is essential to prevent material shortages and production delays. MES integrates with inventory management systems, tracking material usage in real time and automating restocking processes. This prevents overstocking or understocking issues, ensuring materials arrive at the right time to maintain production schedules.

5. Predictive Maintenance to Reduce Downtime

Equipment failures cause unplanned downtime, delaying production and increasing costs. MES uses predictive maintenance tools to monitor machine performance and detect potential failures before they happen. Automated alerts notify maintenance teams when repairs or servicing are needed, preventing breakdowns and extending equipment lifespan.

Automotive manufacturers rely on MES to enhance production processes, improve quality control, and optimize resource allocation. These applications make MES a critical tool for increasing efficiency while reducing costs and minimizing operational risks.

Challenges in Automotive Manufacturing

Automotive manufacturers face complex operational challenges that affect production efficiency, cost control, and regulatory compliance. Meeting industry requirements while maintaining high output levels requires advanced solutions to manage factory operations effectively. MES helps address these obstacles by providing visibility, automation, and process control.

- Supply chain disruptions: Material shortages, supplier delays, and logistical constraints slow production. Manufacturers must adjust schedules and inventory levels to avoid production halts.

- Quality assurance and defect management: Identifying defects early in the process reduces rework and scrap costs. Without a formed tracking system, maintaining consistent product quality becomes difficult.

- Equipment downtime and maintenance inefficiencies: Unexpected equipment failures lead to production stoppages, increasing costs and delaying deliveries. Predictive maintenance and performance monitoring help minimize unplanned downtime.

- Regulatory compliance and traceability: Automotive manufacturers must meet strict safety regulations. Tracking materials, production steps, and testing data ensure compliance while reducing the risk of recalls.

- Production scalability: Expanding production capacity requires standardizing processes across multiple facilities. Without centralized control, scaling operations lead to inconsistencies and inefficiencies.

- Workforce training and process standardization: Operator errors and inefficient workflows reduce production speed. Digital work instructions and automated process controls improve training effectiveness and operational consistency.

- Energy consumption and sustainability requirements: Reducing waste and improving energy efficiency helps manufacturers lower costs and meet goals. Process optimization and resource monitoring provide better control over energy usage.

Manufacturers that address these challenges improve production efficiency, product quality, and overall operational stability. MES provides solutions that help factories optimize resources, reduce costs, and maintain compliance with industry regulations.

How to Improve Efficiency in Automotive Manufacturing with MES

Manufacturers rely on MES to improve production efficiency, reduce operational risks, and optimize factory performance. The system provides data-driven insights, automation tools, and real-time monitoring to streamline processes. These capabilities help factories maintain quality while minimizing costs and production delays.

Automating Data Collection and Process Tracking

Manual data entry slows production and increases the risk of errors. MES automates data collection, capturing real-time production metrics from machines, sensors, and operators. This ensures accurate tracking of key performance indicators (KPIs) such as cycle times, defect rates, and machine utilization. Automated data reporting allows manufacturers to identify inefficiencies and adjust processes to improve productivity.

Optimizing Production Scheduling and Resource Allocation

Balancing production schedules with material availability and workforce capacity prevents delays and inefficiencies. MES synchronizes scheduling with inventory and labor management systems, ensuring that materials arrive on time and operators follow optimized workflows. This reduces bottlenecks, minimizes idle time, and maximizes overall production output.

Enhancing Quality Control with Real-Time Monitoring

Defects impact production costs and customer satisfaction. MES integrates with quality control systems to monitor product specifications, detect anomalies, and flag defects as they occur. Automated alerts notify operators when deviations happen, allowing immediate corrective actions. This reduces waste, improves product consistency, and lowers rework costs.

Implementing Predictive Maintenance to Minimize Downtime

Equipment failures lead to unplanned downtime and increased repair costs. Some MES solutions offer capabilities that address equipment downtime. These systems are capable of collecting data on machine performance and, depending on their features, may be able to predict maintenance requirements using historical data and real-time sensor inputs. This allows for proactive maintenance, with alerts being sent when servicing is needed, which can reduce unexpected failures. The goal of such features is to improve equipment reliability and prolong machine lifespans, minimizing production disruptions.

Standardizing Work Instructions for Consistent Operations

Operators need clear instructions to follow best practices and maintain process consistency. MES provides digital work instructions, ensuring each step of production is performed correctly. These instructions update in real-time based on machine status, production requirements, or regulatory changes. Standardizing workflows improves worker efficiency and reduces errors across multiple shifts and facilities.

Improving Traceability for Compliance and Supply Chain Visibility

Tracking materials, parts, and production processes ensures compliance with industry regulations. MES records each manufacturing stage, linking product batches to raw material sources and assembly data. This improves supply chain visibility and allows manufacturers to trace defects to their origin, reducing liability and improving quality control.

Reducing Waste and Improving Sustainability Efforts

Material waste and energy consumption increase production costs. Some Manufacturing Execution Systems (MES) can offer features that help manufacturers track things like energy use, material waste, and how efficiently materials are being used. This data can then be used to find ways to make processes better, reduce resource consumption, and be more environmentally friendly. If done well, this can help lower costs and meet environmental rules

Manufacturers using MES gain better control over production, improving efficiency while maintaining quality and compliance standards. The system provides the tools to optimize factory operations and reduce costs in an industry.

Evolution of Automotive Manufacturing and MES

Automotive manufacturing has advanced through technological innovations that improve efficiency, safety, and product quality. MES has adapted to support these advancements, providing digital tools that connect production processes and optimize factory operations. The industry's progression reflects a shift toward automation, data-driven strategy, and integrated manufacturing systems.

- Early mass production: The introduction of assembly lines standardized vehicle manufacturing, reducing production time and increasing output. Manual processes dominated, relying on human oversight and repetitive tasks.

- Introduction of automation: Robotics and computer-controlled machinery improved precision and consistency, reducing human error and increasing production speed. Automation helped streamline repetitive tasks while improving safety and efficiency.

- Integration of digital monitoring systems: Manufacturers adopted early versions of MES to track production metrics, monitor machine performance, and manage work orders digitally. These systems provided essential real-time insights but lacked full integration capabilities.

- Expansion of data-driven manufacturing: Advanced MES platforms integrated with ERP and supply chain systems allow manufacturers to analyze performance data and optimize workflows across multiple facilities. Predictive analytics and process automation further improved production efficiency.

- Adoption of smart factories: Modern MES solutions incorporate artificial intelligence, machine learning, and cloud computing to connect production lines with enterprise systems. Smart factories use real-time data to improve traceability, automate and improve production control.

- Sustainability and energy-efficient manufacturing: MES often includes tools for tracking resource consumption, optimizing energy use, and reducing material waste. These capabilities help manufacturers meet standards while lowering operational costs.

Automotive manufacturing continues to grow with advancements in automation, digital connectivity, and sustainability initiatives. MES is vital in supporting these developments, ensuring manufacturers achieve higher efficiency, lower costs, and improved production outcomes.

Key Trends in Automotive Manufacturing and MES

Manufacturers continue integrating innovative technologies into production, improving efficiency and reducing costs through automation and data-driven insights. MES is essential in optimizing factory operations by incorporating artificial intelligence, Internet of Things (IoT) connectivity, and predictive analytics. Cloud-based MES solutions allow greater scalability and system accessibility, reducing the need for expensive on-premise infrastructure. Sustainability initiatives drive the adoption of energy-efficient manufacturing practices, with an MES capable of monitoring real-time resource consumption to minimize waste. Cybersecurity measures remain a priority as factories connect more systems and data sources, ensuring that production information remains secure. MES-ERP integration strengthens business continuity, aligning production workflows with broader enterprise objectives for better inventory control, planning, and efficiency. Automotive manufacturers rely on these advancements to improve quality, reduce downtime, and maintain compliance with industry regulations.

Manufacturers worldwide are adopting cloud-based solutions to improve efficiency, precision, and scalability. At 42Q, we combine decades of manufacturing expertise with cutting-edge technology to deliver innovative, connected manufacturing. Our flexible, cloud-native MES platform enhances visibility, streamlines operations, and accelerates digital transformation. Discover how our solutions can empower your factory to achieve its full potential.

Key Takeaways

- MES improves efficiency in automotive manufacturing by automating workflows, reducing downtime, and providing real-time visibility into production processes.

- Traceability features help manufacturers maintain compliance by tracking materials, components, and assembly processes throughout the production cycle.

- Predictive maintenance reduces machine failures and unplanned downtime by monitoring equipment health and scheduling repairs before breakdowns occur.

- Cloud-based MES solutions enhance scalability and flexibility by integrating factory operations across multiple facilities and improving data accessibility.

- MES-ERP integration strengthens manufacturing operations by aligning production schedules, resource planning, and inventory control with business objectives.

FAQs

MES improves efficiency by automating data collection, optimizing production scheduling, and reducing downtime through predictive maintenance. The system provides real-time monitoring, allowing manufacturers to adjust workflows, minimize bottlenecks, and maintain consistent output. With MES, production processes become more reliable, scalable, and cost-effective.

A comprehensive MES includes production tracking, quality management, resource planning, and traceability features. These components ensure real-time visibility into factory operations, helping manufacturers maintain compliance, reduce waste, and optimize machine utilization. Integrated digital work instructions also enhance operator efficiency and process consistency.

Traceability ensures compliance with safety regulations, reduces liability, and improves quality control by tracking each step in the manufacturing process. MES provides a digital record of materials, assembly processes, and testing data, allowing manufacturers to quickly identify and correct defects. This level of oversight helps prevent costly recalls and production delays.

MES uses machine data and sensor inputs to detect potential equipment failures before they happen. Predictive maintenance strategies reduce unplanned downtime, extend machine lifespan, and lower repair costs. By analyzing performance trends, MES ensures maintenance teams receive timely alerts for servicing, improving overall equipment efficiency.

MES focuses on real-time production management, process automation, and shop-floor monitoring, while ERP handles higher-level business operations like finance, procurement, and supply chain management. MES works with ERP to provide manufacturers with complete operational visibility, ensuring factory processes align with business goals.

15 MES Applications by Industry

15 MES Applications by Industry

Manufacturers constantly seek ways to improve efficiency, reduce costs, and maintain high-quality production standards.

Manufacturing Execution Systems (MES) provide a critical solution by integrating real-time monitoring, automation, and data analytics into production workflows. These applications help manufacturers across various industries track production, optimize resource utilization, and ensure compliance with industry regulations. With the ability to reduce waste, improve traceability, and enhance operational control, MES applications play a key role in modernizing manufacturing and driving long-term growth.

Importance of MES in Manufacturing

Manufacturing Execution Systems (MES) play an essential role in modern production by connecting, monitoring, and controlling complex manufacturing processes. These systems bridge the gap between enterprise resource planning (ERP) and production equipment, ensuring accurate data flow and operational efficiency. As industries strive for greater agility, MES applications provide real-time insights that help you minimize downtime, improve quality, and maximize production output.

Integrating MES applications supports key operational areas, including production scheduling, traceability, quality management, and resource allocation. MES applications make data-driven by providing a centralized view of manufacturing activities, reducing errors, and optimizing workflows. This level of control is significant for industries that rely on precision and compliance, such as automotive, medical devices, and aerospace.

Beyond immediate operational improvements, MES applications also contribute to long-term scalability and cost reduction. With greater visibility into production processes, manufacturers can identify inefficiencies, enhance workforce productivity, and respond more effectively to fluctuations. These advantages make MES applications a critical investment for companies looking to optimize their operations and remain adaptable in data-driven manufacturing.

15 MES Applications by Industry

Manufacturing Execution Systems (MES) provide essential tools for industries that require precision, compliance, and efficiency in production. These applications help manufacturers monitor production in real-time, automate quality control, and improve operational workflows. Below are 15 MES applications categorized by industry, each addressing unique challenges while optimizing manufacturing processes.

Automotive Industry

Automotive manufacturers rely on MES applications to manage complex assembly lines, track components, and improve production efficiency. These systems help optimize workflows, minimize defects, and improve compliance with regulatory standards.

1. Real-Time Production Monitoring

Production inefficiencies result in lost time and increased operational costs. MES applications track production in real-time, collecting data from machinery and operators to identify bottlenecks, optimize throughput, and reduce delays. Manufacturers gain complete visibility into work orders, cycle times, and output, allowing quick adjustments that improve production efficiency.

Effective production monitoring also helps reduce scrap and rework. Immediate alerts notify operators of quality deviations, preventing defective parts from advancing further in the assembly process. This improves overall product consistency and reduces material waste.

2. Quality Assurance and Defect Tracking

Automotive manufacturers must maintain strict quality control throughout production. MES applications integrate with inspection systems to detect defects at early stages, preventing faulty parts from reaching final assembly. Real-time defect tracking making manufacturers to analyze failure trends, improving quality processes over time.

Detailed defect reports allow teams to implement corrective actions quickly, reducing scrap rates and minimizing the risk of expensive recalls. Capturing quality data at every step helps ensure compliance with automotive safety regulations while maintaining high production standards.

3. Traceability and Component Serialization

Manufacturers must track each component through the production cycle to ensure compliance with regulatory standards. MES applications provide full traceability by assigning serial numbers to components and recording their history, from supplier sourcing to final vehicle assembly.

Serialized traceability simplifies recall management by identifying specific batches of defective parts rather than requiring full-scale product recalls. This improves accountability while reducing liability risks for manufacturers and suppliers.

4. Just-in-Time (JIT) Inventory Management

Managing inventory efficiently prevents production delays and minimizes unnecessary costs. MES applications coordinate material deliveries with production schedules, ensuring that parts arrive when needed. This reduces excess stock, prevents shortages, and optimizes warehouse space.

Automated inventory tracking helps reduce lead times and improves supply chain reliability. Keeping inventory levels aligned with production grow minimizes waste while supporting lean manufacturing principles.

5. Workforce and Task Allocation

Optimizing labor allocation improves productivity and reduces idle time. MES applications assign tasks based on worker availability, skill levels, and production priorities, ensuring that each station operates efficiently.

Smart scheduling improves resource utilization by aligning work assignments with operational needs. Skill-based allocation reduces human errors, while digital work instructions provide operators with step-by-step guidance to improve efficiency.

Medical & Pharmaceutical Industry

Strict regulatory requirements make MES applications essential in medical and pharmaceutical manufacturing. These systems ensure compliance, track product quality, and improve documentation accuracy.

6. Electronic Batch Record (EBR) Management

Paper-based record-keeping increases the risk of human errors and non-compliance. MES applications digitize batch records, ensuring accurate and complete documentation for every production run.

Electronic batch records improve traceability and simplify audit preparation. Manufacturers can store, retrieve, and update production data in a centralized system, reducing paperwork and ensuring compliance with industry standards such as FDA 21 CFR Part 11.

7. Real-Time Process Monitoring

Precise control over production conditions ensures product safety and consistency. MES applications monitor temperature, pressure, and humidity in real-time, preventing deviations that could compromise product integrity.

Automated alerts notify operators of variations in process conditions, reducing the risk of contamination or defective batches. This level of monitoring supports Good Manufacturing Practices (GMP) and improves regulatory compliance.

8. Regulatory Compliance Support

Regulatory agencies require detailed production records and audit trails. MES applications automate compliance reporting, reducing the manual effort needed to prepare for audits.

Automated compliance tracking helps ensure that all manufacturing processes adhere to industry regulations. Digital logs provide transparency and prevent errors in documentation, reducing the risk of regulatory violations.

9. Equipment Calibration and Maintenance Tracking

Maintaining properly calibrated equipment is essential for consistent product quality. MES applications track calibration schedules and log maintenance activities to prevent equipment failures.

Automated maintenance reminders reduce unplanned downtime and extend asset lifespan. Preventive maintenance ensures machines operate at peak performance, supporting reliable and repeatable production processes.

10. Batch and Product Traceability

Tracking raw materials and final products improves product safety and recall management. MES applications provide complete traceability from ingredient sourcing to final packaging.

Automated traceability reduces risks associated with contamination or defects. When recalls are necessary, manufacturers can quickly identify affected batches, reducing financial losses and protecting consumer safety.

Food and Beverage Industry

Food manufacturers use MES applications to improve safety, maintain quality standards, and optimize production workflows. These systems provide real-time process monitoring and automate compliance tracking.

11. Recipe and Ingredient Management

Precision in ingredient measurements ensures product consistency. MES applications store digital recipes and track ingredient usage to prevent formulation errors.

Standardized recipe management reduces variability between batches. Automated recipe enforcement helps manufacturers maintain uniform product quality across different production facilities.

12. Food Safety and Compliance Tracking

Food manufacturers must meet strict safety regulations. MES applications monitor processing conditions, track ingredient sources, and automate compliance reporting.

Automated food safety tracking prevents contamination risks and simplifies regulatory audits. Digital logs provide proof of compliance with safety standards, reducing legal and financial risks for manufacturers.

13. Production Scheduling and Workflow Optimization

Optimizing production workflows improves efficiency and reduces operational costs. MES applications balance workloads, align production with market, and prevent bottlenecks.

Real-time scheduling adjustments help manufacturers meet order deadlines without unnecessary delays. Better workflow management improves labor efficiency and reduces raw material waste.

14. Waste Reduction and Yield Optimization

Minimizing waste lowers costs and improves profitability. MES applications analyze production data to identify inefficiencies, allowing manufacturers to optimize ingredient usage and reduce overproduction.

Data-driven insights help manufacturers refine processes to maximize yields. Reduced food waste improves sustainability efforts while increasing operational efficiency.

15. Packaging and Labeling Verification

Accurate labeling is essential for regulatory compliance and consumer safety. MES applications automate packaging processes, verifying ingredient lists, expiration dates, and nutritional information.

Automated label verification prevents mislabeling errors, reducing product recalls. Consistent labeling ensures that consumers receive accurate information while meeting compliance requirements.

Benefits of Implementing MES Applications

Manufacturing Execution Systems (MES) improve production efficiency, reduce operational costs, and enhance product quality by providing real-time visibility and process automation. These applications support manufacturers in industries where precision, compliance, and scalability are critical. Implementing MES applications leads to measurable improvements across production lines, supply chain operations, and workforce management.

- Improved Production Efficiency: Automating workflows reduces manual data entry, minimizes human errors, and accelerates production cycles. MES applications provide real-time monitoring of manufacturing activities, allowing manufacturers to identify bottlenecks and optimize machine utilization. A data-driven approach to production management helps reduce downtime, improve throughput, and streamline daily operations.

- Enhanced Product Quality and Traceability: Tracking materials, monitoring process parameters, and logging quality inspections at every production stage ensures consistent product quality. MES applications detect deviations in real-time, allowing operators to make immediate corrections. Full traceability simplifies compliance with industry regulations and improves response times for recalls or quality-related investigations.

- Cost Reduction Through Waste Minimization: Manufacturing waste leads to unnecessary costs and inefficiencies. MES applications analyze production data to identify where waste occurs, helping manufacturers adjust processes to improve material usage. Automating defect detection and optimizing workflows reduces scrap rates while ensuring that raw materials are used efficiently.

- Regulatory Compliance and Audit Readiness: Industries with strict compliance requirements benefit from automated documentation and compliance tracking. MES applications generate and store digital production records, ensuring that all manufacturing data is readily available for audits. Standardized reporting reduces the risk of regulatory violations and simplifies certification processes.

- Better Workforce Utilization: Assigning tasks based on skill levels, availability, and production priorities optimizes labor resources. MES applications automate workforce scheduling, reducing idle time and improving overall productivity. Digital work instructions help operators complete tasks more efficiently, reducing training time and minimizing errors.

- Seamless Integration With Supply Chain Operations: Synchronizing production schedules with material deliveries prevents disruptions caused by shortages or excess inventory. MES applications provide real-time updates on stock levels, helping manufacturers manage materials efficiently. Improved coordination between suppliers, manufacturers, and distributors ensures that production stays aligned with orders.

- Predictive Maintenance for Equipment Reliability: Equipment downtime disrupts production and increases costs. MES applications track machine performance data, detecting signs of wear or potential failures before breakdowns occur. Predictive maintenance reduces unplanned downtime, extends asset lifespan, and helps manufacturers maintain consistent production output.

- Scalability for Expanding Operations: Standardized processes and centralized data management allow manufacturers to scale operations without unnecessary complexity. Cloud-based MES applications provide multi-site visibility, allowing manufacturers to monitor and manage production across multiple facilities. Consistent workflows improve efficiency while supporting long-term growth.

Implementing MES applications allows manufacturers to improve efficiency, reduce operational risks, and maintain high-quality production standards. These systems provide a foundation for data-driven helping companies optimize resources while meeting industry compliance requirements. MES adoption supports manufacturers in achieving greater operational control, cost savings, and long-term scalability.

Future Trends in MES Applications

Manufacturing Execution Systems (MES) continue to move with advancements in automation, data analytics, and cloud computing. As manufacturers seek greater efficiency, flexibility, and visibility across operations, MES applications are integrating new technologies to meet industry grows.

Artificial intelligence (AI) and machine learning improve predictive analytics in MES applications, allowing manufacturers to optimize production scheduling, identify potential failures before they occur, and enhance quality control through automated defect detection. AI-driven insights help manufacturers make data-backed decisions that improve efficiency and reduce costs.

Cloud-based MES solutions provide multi-plant connectivity, allowing manufacturers to manage global operations through a centralized platform. Cloud deployment reduces infrastructure costs while ensuring real-time access to production data from any location. This shift supports manufacturers looking for scalable, remote-accessible solutions that improve collaboration between production sites.

Integration with the Industrial Internet of Things (IIoT) is improving data collection and equipment monitoring. Smart sensors connected to MES applications provide real-time machine performance data, helping manufacturers track overall equipment effectiveness (OEE), automate maintenance scheduling, and reduce unplanned downtime.

Augmented reality (AR) and digital twin technology enhance training and troubleshooting capabilities. AR-enabled MES applications allow technicians to visualize production processes, receive step-by-step guidance, and interact with digital representations of equipment for more efficient maintenance and problem-solving.

Cybersecurity is becoming a priority as MES applications handle increasing production data. Enhanced security features, including multi-factor authentication, encryption, and secure cloud storage, ensure manufacturers protect sensitive information while complying with industry regulations.

MES applications will continue integrating with emerging technologies to improve manufacturing efficiency, quality control, and supply chain coordination. As automation and data-driven processes advance, manufacturers will rely on MES solutions to maintain operational agility and optimize production.

Manufacturers worldwide embrace cloud-based solutions to achieve efficiency, precision, and scalability. At 42Q, we combine decades of manufacturing expertise with cutting-edge technology to deliver smart, connected manufacturing. Our flexible, cloud-native MES platform enhances visibility, streamlines operations, and accelerates digital transformation. Discover how our solutions can empower your factory to achieve its full potential.

Key Takeaways

- MES applications improve production efficiency by automating workflows, reducing errors, and optimizing machine utilization to minimize downtime and maximize output.

- Real-time monitoring and quality tracking enhance product consistency by detecting defects early and ensuring compliance with industry standards.

- Automated inventory and supply chain management prevent material shortages and overstocking, improving operational agility and cost efficiency.

- Regulatory compliance and audit readiness are simplified through digital records, automated reporting, and process standardization.

- Predictive maintenance features reduce equipment downtime by monitoring performance data and scheduling proactive maintenance before failures occur.

FAQs

An MES application is a software solution that monitors, tracks, and controls production processes in real time. It provides manufacturers with visibility into operations, automates data collection, and optimizes production workflows to improve efficiency and quality.

MES applications reduce manual data entry, minimize errors, and streamline workflows by automating production monitoring and scheduling. Real-time insights help manufacturers identify bottlenecks, allocate resources effectively, and minimize downtime to improve overall efficiency.

Industries such as automotive, aerospace, medical devices, food and beverage, and electronics manufacturing benefit significantly from MES applications. These sectors require precision, regulatory compliance, and real-time traceability, all of which MES applications provide.

MES applications automate documentation, track production data, and generate audit-ready reports. By maintaining digital records and enforcing process controls, MES solutions help manufacturers meet regulatory requirements in industries with strict compliance standards.

MES focuses on shop floor execution, providing real-time visibility into production processes, equipment performance, and quality control. ERP systems manage broader business functions such as finance, procurement, and supply chain management. Integrating MES with ERP ensures seamless coordination between production and enterprise operations.

What Are OEE Systems in Manufacturing?

What Are OEE Systems in Manufacturing?

Manufacturers rely on Overall Equipment Effectiveness (OEE) to assess and improve production efficiency.

Measuring availability, performance, and quality helps identify bottlenecks, reduce unplanned downtime, and enhance productivity. Manufacturers struggle to maintain consistent output and operational reliability without accurate OEE tracking.

OEE systems in manufacturing provide actionable insights that allow businesses to improve machine utilization, streamline workflows, and optimize resource allocation. Understanding how to measure and apply OEE metrics reduces waste, improves product quality, and ensures production runs efficiently.

What Does OEE Stand For in Manufacturing?

Overall Equipment Effectiveness (OEE) is a standardized metric that quantifies manufacturing productivity by measuring how efficiently equipment operates. It evaluates three critical factors—availability, performance, and quality—to determine the percentage of planned production time that is genuinely productive. A perfect OEE score of 100% indicates flawless manufacturing: no unplanned downtime, no slow cycles, and zero defects.

Manufacturers rely on OEE to pinpoint inefficiencies, track continuous improvement initiatives, and optimize production output. By providing real-time visibility into equipment effectiveness, OEE systems in manufacturing help identify bottlenecks, reduce waste, and increase throughput. Understanding this metric is essential for improving operational efficiency and maintaining a driving edge in modern production situations.

Importance of OEE Systems in Manufacturing

OEE systems in manufacturing provide a structured approach to identifying and eliminating inefficiencies in production. Every unplanned stoppage, slow cycle, or defective product directly affects output and profitability. Without accurate data on these losses, manufacturers struggle to implement meaningful improvements. OEE systems quantify equipment effectiveness, offering clear insights into performance trends and production constraints.

Operational visibility is essential for improving production efficiency and reducing waste. OEE data helps manufacturers identify recurring downtime causes, assess equipment performance, and implement targeted maintenance strategies. Instead of reacting to breakdowns, businesses can shift to proactive measures that extend machine lifespan, optimize workforce utilization, and maximize throughput.

Key Components of OEE in Manufacturing

OEE systems in manufacturing evaluate equipment efficiency using three fundamental metrics: availability, performance, and quality. Each component identifies specific production losses and provides insight into areas requiring improvement. Understanding these factors helps manufacturers reduce downtime, optimize production speed, and improve product quality.

Availability: Minimizing Downtime and Maximizing Production Time

Availability measures the percentage of planned production time that equipment remains operational. Downtime caused by unplanned maintenance, changeovers, or raw material shortages reduces production efficiency. OEE systems track planned and unplanned stoppages, providing data that helps manufacturers address recurring issues.

Several factors contribute to availability losses, including unexpected equipment failures, lengthy setup times, and delayed material deliveries. Preventive maintenance programs, standardized changeover procedures, and better inventory management reduce disruptions. Increasing machine uptime ensures that production schedules remain consistent, improving manufacturing efficiency.

Performance: Ensuring Optimal Production Speeds

Performance evaluates how efficiently equipment operates compared to its designed capacity. Machines running at slower-than-expected speeds or experiencing frequent micro-stoppages contribute to performance losses. These inefficiencies reduce output without directly halting production, making them difficult to detect without real-time monitoring.

OEE tracking helps manufacturers identify process inefficiencies such as slow cycle times, suboptimal machine settings, and worn-out tooling. Addressing these issues improves production rates while maintaining consistent quality. Proper operator training, proactive machine adjustments, and automated process monitoring support higher performance levels.

Quality: Reducing Defects and Improving Product Consistency

Quality measures the percentage of manufactured products that meet specifications without requiring rework or scrap. Defective products lead to waste, increased costs, and additional labor for corrections. OEE systems track defect rates, providing insights into production inconsistencies and recurring quality issues.

Several factors, including improper machine calibration, inconsistent raw materials, and operator errors, contribute to quality losses. Real-time quality monitoring, automated defect detection, and process standardization help manufacturers maintain high product standards. Identifying and addressing the root causes of defects reduces material waste, improves customer satisfaction, and enhances overall production reliability.

How These Components Work Together

Availability, performance, and quality are connected, with losses in one area often affecting the others. A machine experiencing frequent downtime (availability loss) may also struggle to maintain optimal cycle times (performance loss). Likewise, running equipment at maximum speed without proper quality controls may lead to increased defects (quality loss).

OEE systems in manufacturing provide a structured approach to measuring and improving these key components. Tracking and analyzing OEE data helps manufacturers implement targeted improvements that enhance equipment reliability, increase throughput, and maintain high-quality production standards.

Benefits of Implementing OEE Systems in Manufacturing

OEE systems in manufacturing provide valuable insights that help manufacturers improve efficiency, reduce production losses, and maintain consistent product quality. Measuring availability, performance, and quality allows businesses to identify inefficiencies and take targeted actions that enhance productivity. Tracking OEE metrics provides a structured approach to minimizing downtime, improving machine reliability, and increasing output without requiring additional resources.

- Reduced Downtime and Unplanned Stoppages: Equipment failures and unexpected maintenance issues disrupt production schedules and reduce output. OEE tracking provides real-time data on recurring downtime causes, allowing manufacturers to implement proactive maintenance strategies. Predictive maintenance based on historical trends helps reduce breakdowns, ensuring machines operate reliably and production schedules remain uninterrupted.

- Increased Production Efficiency: Machines that operate below optimal speeds or experience frequent micro-stoppages lead to performance losses. OEE monitoring identifies slow-running equipment, enabling manufacturers to make necessary adjustments. Process optimization, better operator training, and automated tracking tools help improve production rates, ensuring machines perform at their designed capacity.

- Improved Product Quality and Defect Reduction: Defective products lead to material waste, rework, and increased operational costs. OEE systems track defect rates and identify patterns that indicate process inconsistencies or equipment malfunctions. Early detection of quality issues allows manufacturers to implement corrective actions before large-scale defects occur, maintaining high product standards while reducing scrap and rework expenses.

- Lower Operational Costs and Better Resource Utilization: Production inefficiency wastes valuable resources, from raw materials to labor hours. OEE data helps manufacturers optimize resource allocation by ensuring equipment operates efficiently, and workforce utilization remains balanced. Reducing material waste, minimizing energy consumption, and optimizing production workflows contribute to significant cost savings over time.

- Data-Driven Regulating for Continuous Improvement: Accurate and detailed production data allows manufacturers to identify trends and measure the effectiveness of process improvements. OEE reports provide insights into production bottlenecks, enabling businesses to implement data-backed changes that drive continuous operational improvements. Historical data tracking helps assess long-term trends and ensures sustained productivity gains.

- Sustainability and Waste Reduction: Manufacturing operations generate excess waste when inefficient processes or production defects occur. OEE tracking helps minimize unnecessary waste by improving equipment reliability, reducing defective output, and streamlining production workflows. Efficient manufacturing practices contribute to lower energy consumption and a reduced footprint, aligning with sustainability goals while maintaining cost-effective operations.

OEE systems in manufacturing provide structured insights that support efficiency improvements at every production stage. Tracking availability, performance, and quality metrics ensure manufacturers can pinpoint inefficiencies, reduce costs, and maintain a high standard of production output. Implementing OEE-driven improvements leads to measurable gains in productivity, operational stability, and long-term manufacturing success.

Real-World Applications of OEE in Manufacturing

OEE systems in manufacturing are widely used across industries to improve production efficiency, reduce downtime, and maintain high-quality standards. Manufacturers rely on OEE tracking to optimize processes, minimize losses, and ensure consistent output. Each industry applies OEE data to address specific challenges, from reducing machine failures in high-volume production to maintaining strict compliance in regulated sectors.

Automotive Production: Optimizing Assembly Line Efficiency