Case Study

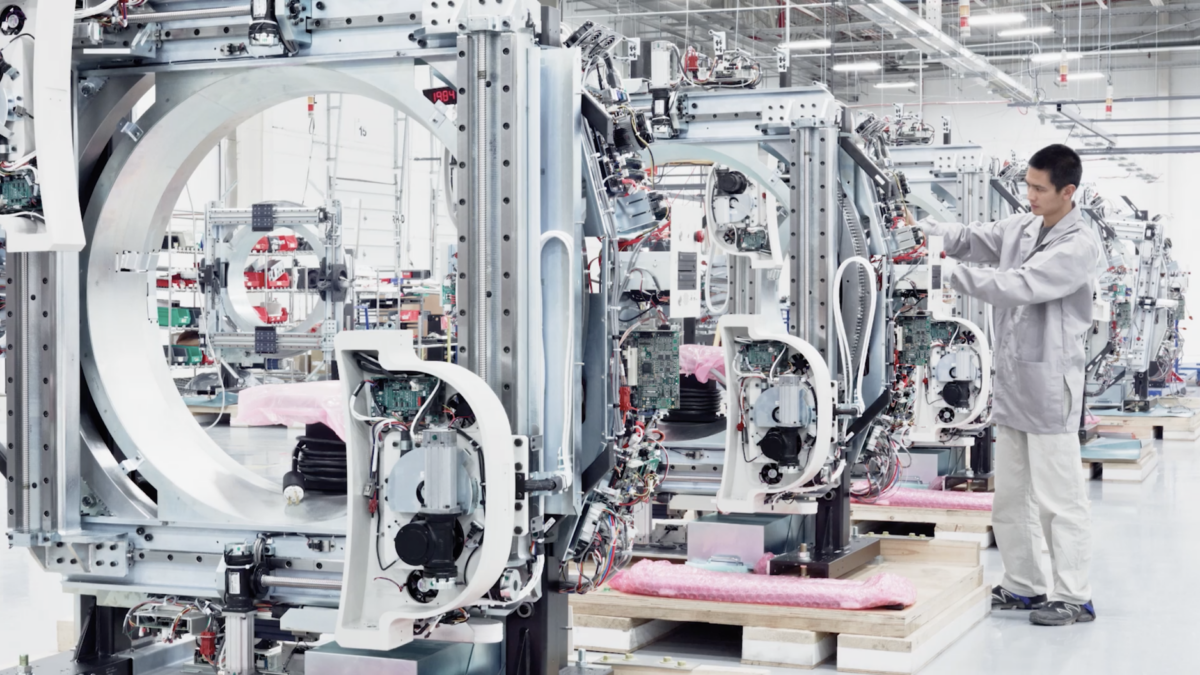

Digital Factory Transformation with 35,000 Pieces of Manufacturing Equipment Connected in the Cloud

The Challenge

Sanmina manufactures 250 million products per year. More of a challenge is that there are over 200,000 different top-level assemblies produced each year for 700 different OEM customers with up to 20,000 forecast changes per week. The OEMs operate in diverse industries including telecommunications, enterprise computing & storage, and industrial and clean technology. A significant amount of production is for medical, aerospace and automotive products with strict regulatory requirements. The existing on-premise MES required significant maintenance and upgrade efforts from the IT and operations teams. It was also limited in its ability to manage supply chains beyond the walls of each factory, and was not well suited for factory automation and other IIoT Initiatives.

Why 42Q

42Q offers a full-featured global cloud-based system capable of integrating product yield, WIP and inventory information across a global network of 10,000 suppliers delivering components to 50 manufacturing facilities in 15 countries around the world. Many of these factories supply sub-assemblies to PCBA and systems integration facilities. The solution accommodated Sanmina’s diverse manufacturing processes including enclosure fabrication, PCBA manufacturing and complex systems integration. It also complies with regulatory requirements in medical, aerospace and automotive industries.

Solution

- A unified virtual cloud factory (digital twin) provides global factory and supply chain visibility, including real-time WIP, yield and throughput data for 50 factories.

- Following implementation, plants self deployed the cloud-based MES with no support from I.T. or 42Q. Because of this, 42Q was rapidly adopted and its use expanded.

- A visual factory monitors yield, throughput, work-in-process (WIP) ageing, against predefined targets. It provides real-time status at product, workstation, production floor, plant, regional and global levels.

- Production lines in 42Q are programmed so alerts are sent to technicians, engineers or management when WIP, yields or throughput drops below predefined limits.

- Multi-level supply chain visibility provides real-time component delivery information from suppliers, real-time status on work orders in factories manufacturing sub-assemblies including PCBs, enclosures and PCBAs.